Dissatisfaction in injection molding jargon is also called undershot or short shot, insufficient filling, and part dissatisfaction. It refers to partial incompleteness at the end of the injection plastic flow or partial filling in a multi-cavity mold, especially the thin-walled area or the end of the flow path. area. It is manifested that the melt condenses before filling the cavity, and the molten material is not fully filled after entering the cavity, resulting in a lack of material in the product.

What causes dissatisfaction with injection molding?

The main reason for the short shot is that the flow resistance is too large, so that the melt cannot continue to flow. Factors affecting melt flow length include: part wall thickness, mold temperature, injection pressure, melt temperature and material composition. These factors can lead to short bets if not handled properly.

Hysteresis effect: also known as stagnation, if there is a relatively thin structure, usually a rib, etc., at a position close to the gate, or perpendicular to the flow direction, then during the injection molding process, the melt passes through this position. It will encounter a relatively large forward resistance, and in the flow direction of the main body, due to the smooth flow, the flow pressure cannot be formed. Only when the melt is filled in the main body direction or enters the holding pressure will it form a sufficient pressure. The stagnation part is filled, and at this time, because the position is very thin, and the melt does not flow without heat supplement, it has solidified, thus causing underfilling.

How to solve the injection molding dissatisfaction?

1. Remedy for under-injection defects:

Material

Increase the fluidity of the melt

Reduce the addition of recycled materials

Reduced gas decomposition in raw materials

Mold design

The location of the gate ensures that it fills the thick walls first to avoid stagnation, which can lead to premature hardening of the polymer melt.

Increase the number of gates and reduce the flow ratio.

Increase runner size and reduce flow resistance

The position of the exhaust port is properly set to avoid the phenomenon of poor exhaust (see whether the under-injection part is burnt)

Increase the number and size of exhaust ports

Increase the design of cold material well to discharge cold material

The distribution of cooling water channels should be reasonable to avoid causing the local temperature of the mold to be low.

Injection molding machine

Check whether the check valve and the inner wall of the barrel are severely worn, which will lead to serious loss of injection pressure and injection volume

Check whether the feeding port has material or whether it is bridged

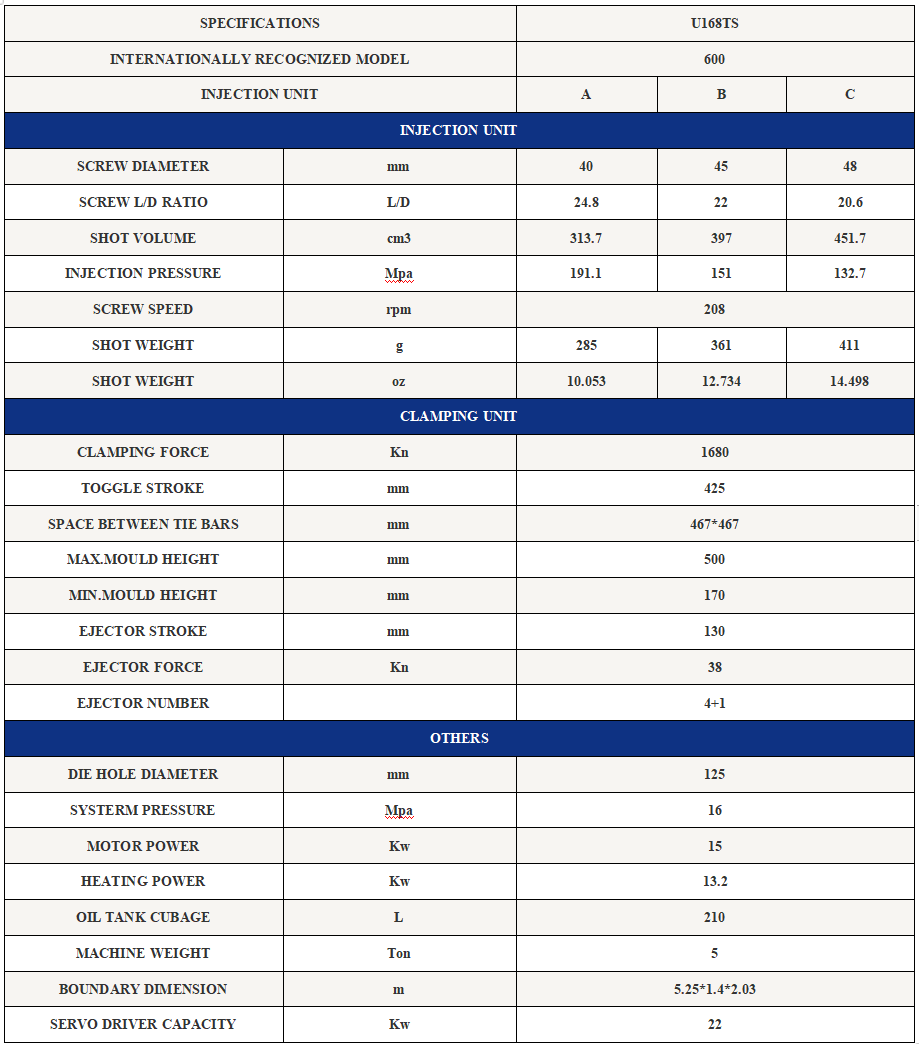

Check whether the ability of the injection molding machine can meet the molding requirements

Process conditions

Increase injection pressure

Increase injection speed, enhance shear heat

Increase injection volume

Increase barrel temperature and mold temperature

Increase the melt length of the injection molding machine

Reduce the buffer amount of the injection molding machine

Extended injection time

Reasonably adjust the position of each injection segment and the corresponding speed and pressure

Parts design

The wall thickness design of the part is too thin

Stiffeners that cause stagnation in the part

There is a big difference in the thickness of the parts, causing stagnation in the local area, which cannot be avoided by mold design

2. Measures to solve the problem of stagnation and under-injection:

1) Increase the thickness of the stagnation part, and the thickness difference of the parts should not be too large. The disadvantage is that it is easy to cause sink marks.

2) Change the gate position to the end of the filling, so that pressure is formed at this position.

3) When injection molding, first reduce the speed and pressure, so that a thick solidified layer is formed at the front of the material flow in the early stage of filling, and it is considered that increasing the melt pressure is a commonly used measure.

4) Use materials with good fluidity.