PET bottle preform design

The PET preform is very important because it is the basis for injection molding of the preform and the key to further blow molding. Therefore, if the customer has certain production and quality requirements for the preform, our team of experienced preform designers and engineers will help the customer to analyze and provide suggestions for optimizing the preform design to speed up the development of the preform.

PET bottle preform mold design

Once the design optimization of the preform is complete, Sonly will improve the mold design to make it easier to handle, more robust and less expensive. Excellent PET preform mold design can help improve the quality of the mold and ensure that the preform products will not have defects such as air bubbles, different sizes, and eccentricity during the injection molding process.

PET bottle preform injection factory solution

If customers want to build their own PET preform injection molding factory, Sonly can provide professional design guidance, including factory injection workshop planning and design and water/air/electricity detailed layout design. In this way, customers can get a complete injection molding plant planning plan in the shortest time to start the construction of the plant.

Respond quickly to customer needs

Sonly's services for customers run through the entire project: from preform design to injection molding equipment, factory construction layout to perfect after-sales support, etc. Therefore, if customers need us, we are always on call to carry out any problems and troubleshooting. Respond and resolve quickly, which reduces design and work cycles during project development and increases productivity in the long run.

Engineer service On-site guidance service

Provide engineer services at the customer site to quickly run the PET preform factory: Dakumar engineers will help customers install the entire production line and stabilize production by inspecting and planning the construction of the workshop. The advantage of this is that the new production line can run quickly under the guidance of expert engineers, reducing customer waiting time and getting products to market as soon as possible.

Provide training services for customer employees

In addition to providing engineer services for running PET preform production lines, Sonly also provides training for customer employees who will operate machines and molds. Long-term training programs can be provided, and the initial on-site training is generally provided, including basic operation and maintenance. In this way, the new PET preform production line can work more stably and for a long time.

Customized services for flexible needs

As different customers will have different needs, we will provide appropriate service and support to help them.

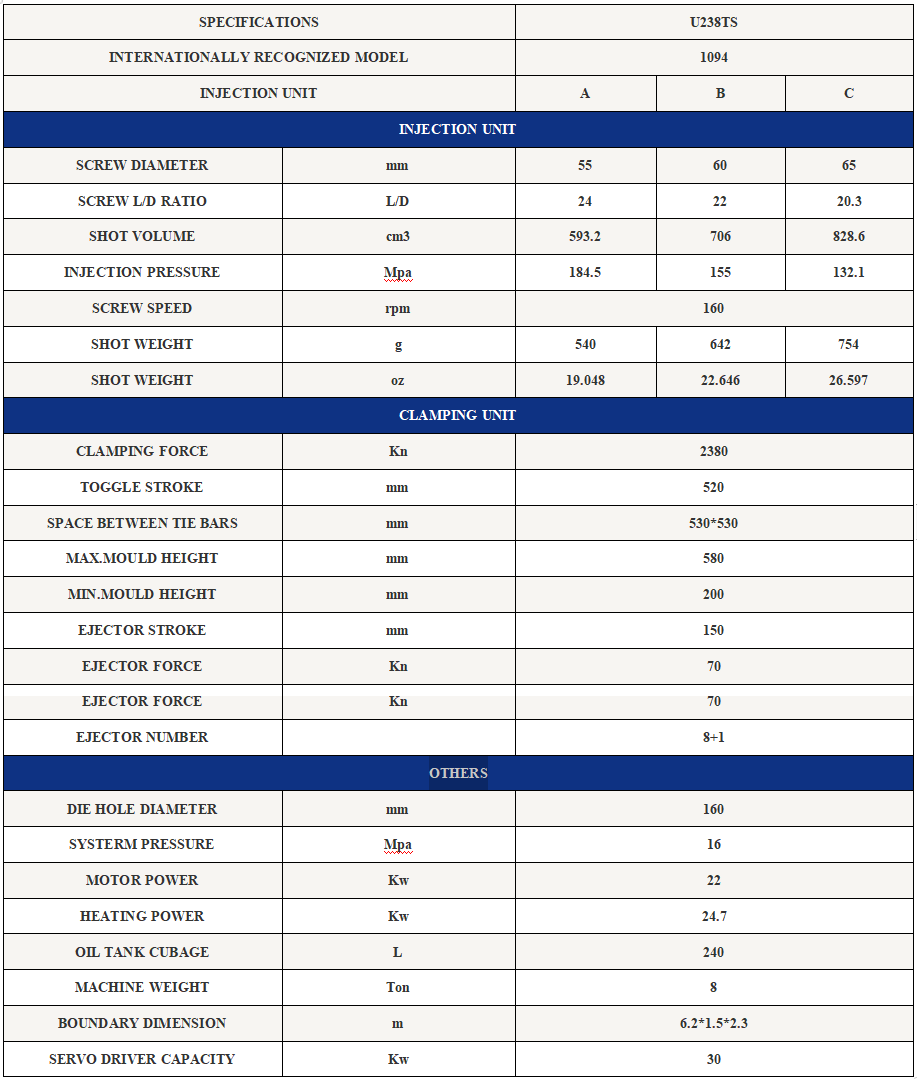

Main Features:

One.The Lock Section

1.Arch template, effectively protects the mould, especially suitable for big template with small mold.

2.The electric ruler is installed on the crosshead, the position is more precise.

3.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly

4.The connected tail-board stills itself with big lock shaft, improves tail-board strength, and ensures zero abrasion of the tail-board, easy for maintenance.

5.Connected movable plate, improves its rigidity and reduces deformation

6.Connected thrust bearing, improves its strength and stills itself with small lock shaft, ensures zero abrasion.

7.Arch template fully complies with mechanical property, largely improves template strength.

8.More reasonable toggle design, speeds and stabilizes mold opening and closing.

9.Adjustable movable plate mounting plate, makes the installation easier.

10.Mixed design of T-shape groove and die hole, increases universality of the mold.

Two.The Injection Section.

1.Bridge type support, improves injection smoothness.

2.Longer length-diameter ratio screw design, improves plasticizing effect.

3.Double seal structure, ensures no oil leakage.

4.Withhold type press plate, easy for debugging and assembly.

5.Bijection structure, improves stability.