PET tube preform debugging technology

The chemical name of PET is polyethylene terephthalate, also known as polyester. At present, GF-PET is the most used among customers, mainly for the production of preforms. No matter what product we make, there will always be various problems before and during production, so how should we prevent it before production? How to solve problems in the production process?

Today, we will share with you the years of manufacturing experience of our technicians in terms of "how to prevent before production" and "common PET adjustment problems".

1. Prevention before childbirth

Handling of plastics

Because the PET macromolecules contain lipid groups and have a certain degree of hydrophilicity, the pellets are more sensitive to water at high temperatures. When the water content exceeds the limit, the molecular weight of PET decreases during processing, and the products become colored and brittle. Due to this, the material must be dried before processing, and the drying temperature is 150 ° C and kept for more than 4 hours. Our treatment for this is generally 170 ℃, 3-4 hours. After this, the air shot method is used to check whether the material is completely dry. Generally, the proportion of recycled materials should not exceed 25%, and the recycled materials should be thoroughly dried.

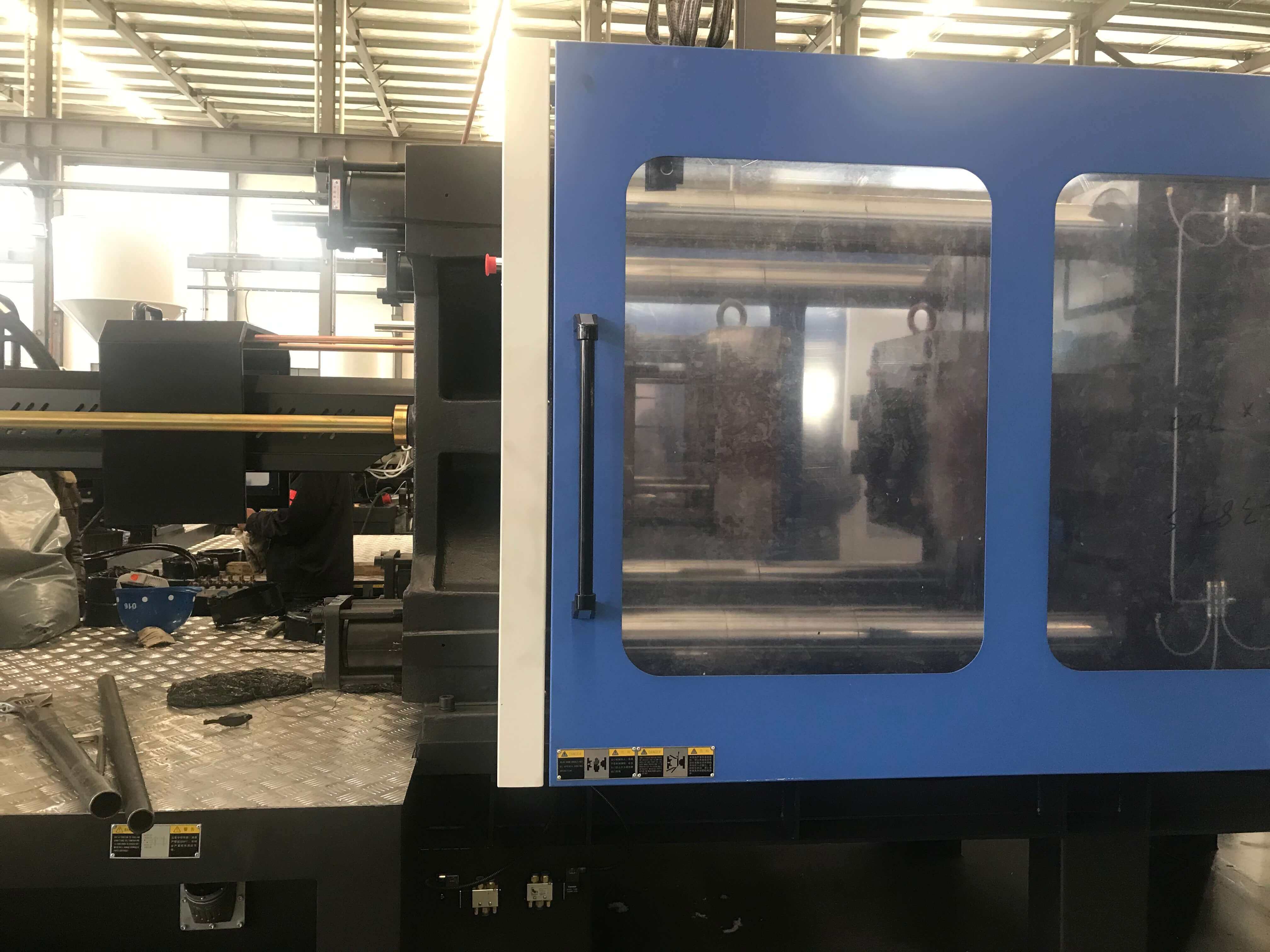

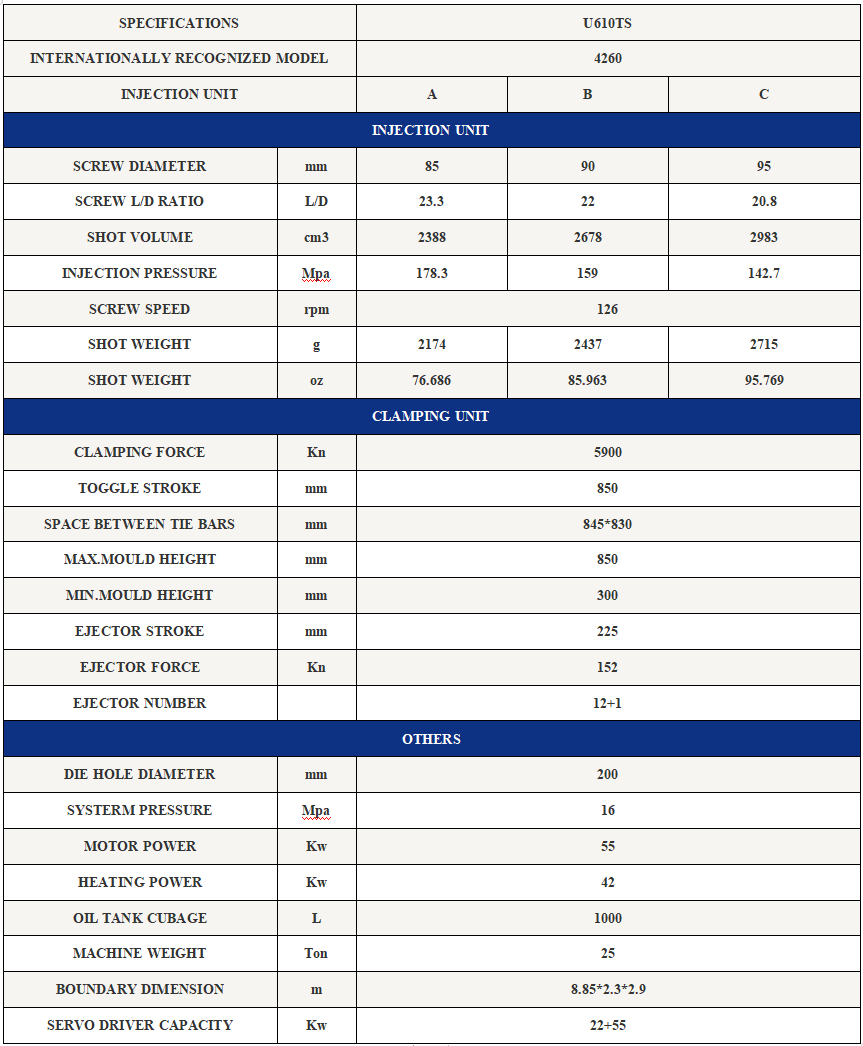

Selection of injection molding machine

Because PET has a short stable time after melting point and high melting point, it is necessary to choose an injection system with more temperature control sections and less self-friction heat generation during plasticization, and the actual weight of the product (water-containing material) should not be less than machine injection. 2/3 of the amount.

Mold and gate design

PET preforms are generally formed by hot runner molds. It is best to have a heat insulation board between the mold and the injection molding machine template, and its thickness is about 12mm, and the heat insulation board must be able to withstand high pressure. The exhaust must be sufficient to avoid local overheating or fragmentation, but the depth of the exhaust port should generally not exceed 0.03mm, otherwise it is easy to produce flash.

Injection molding machine settings

① Melting temperature: it can be measured by air-shot method. 270-295℃, the enhanced GF-PET can be set to 290-315℃, etc.

② Injection speed: Generally, the injection speed is fast, which can prevent premature solidification during injection. Shots are usually completed within 4 seconds.

③ Back pressure: the lower the better, to avoid wear. Generally not more than 100bar, usually do not need to use.

2. Common tuning problems

Poor cooling

reason:

① Mold cooling system is not good

Check and solution:

Check the water system (pressure, flow, temperature); check the mold water channel (the core water pipe, the mold cavity); increase the cooling time.

② The temperature is too high

Inspection and solution: reduce machine temperature and mold temperature.

③ Insufficient or too large holding pressure

Inspection and solution: increase or decrease the holding time; increase or decrease the holding pressure.

④ The mold surface is wet

Check and solution: Adjust the workshop temperature.

⑤ The position of the manipulator is wrong

Check and solution: Re-alignment

shrink

reason:

① Insufficient injection

Inspection and solution: increase the injection volume; reduce the conversion time; increase the holding pressure time

② Poor cooling

Inspection and solution: check the water system (pressure, flow, temperature); check the mold water channel (mold core water pipe, mold cavity); increase the cooling time.

③ Excessive suction

Inspection and solution: reduce the location and time of glue pumping

④ The temperature is too high

Inspection and solution: reduce machine temperature and mold temperature

⑥ The position of the valve needle is incorrect

Inspection and solution: maintenance of hot runner