Overview of Servo Energy-Saving Technology Early injection molding machines were mainly hydraulic, and their contribution to energy saving and environmental protection was obviously weak. All-electric injection molding machines were the most representative equipment technology in terms of energy saving and environmental protection. The main difference between the two lies in the servo motor. The use of the oil-electric hybrid injection molding machine has the advantages of hydraulic and servo.

In addition, when the hydraulic press maintains high pressure and high output for a long time, it still has the advantage that the full motor cannot completely replace it. Therefore, the full hydraulic system with energy saving and environmental protection is also the most potential equipment technology at this stage.

The difference between traditional quantitative pump and servo system The injection molding machine can be decomposed into several stages such as mold clamping, injection/pressure holding, feeding, cooling, mold opening, and ejection from the standard action, and each stage needs to provide different and appropriate pressure. And flow, for the oil pump motor, the injection molding process is a variable load state.

In the hydraulic system of the fixed pump, the motor continuously provides a constant flow at a constant speed. Although the proportional pressure and flow proportional valve (EFBG) can achieve the results of the required pressure and flow ratio configuration at each stage, the hydraulic pressure other than the required control can be achieved. The oil must still drain back to the tank. For the injection molding machine, the power consumption caused by the output power consumption is continuous, that is to say, if the injection molding machine is in the standby state, the quantitative pump will continue to provide a constant flow and directly discharge it back to the fuel tank, resulting in a considerable and unnecessary power cost. The control technology of the servo system can improve the shortcomings of the above-mentioned quantitative pump hydraulic system.

The servo motor transmits the signal back to the driver through the encoder for precise rotation control, so that the flow demand of the controlled hydraulic oil is directly output by the oil pump, that is to say, the size of the output flow is obtained by the increase or decrease of the precise speed control.

In terms of hydraulic oil pressure control, the pressure sensor connected in series on the oil pump transmits the pressure signal result back to the driver for continuous closed-loop control, so as to achieve the purpose of precise pressure control. In this way, the servo control system can accurately provide The pressure and flow required for each stage of injection molding can greatly reduce the output power consumption compared with the quantitative pump system.

The principle of energy saving in injection molding From the perspective of power consumption at each stage of injection molding, the two stages of feeding and cooling are long-term actions, and their power is most worth saving, especially cooling. The servo system does not need any work for the injection molding machine. In other words, the product The longer the cooling time in the molding cycle, the more significant the energy saving benefits.

The composition of the servo energy-saving system of injection molding machine The standard composition of the servo energy-saving system of full hydraulic injection molding machine is generally composed of three components: servo motor, driver and oil pump group.

Servo motors are divided into AC induction servo and permanent magnet servo (synchronous servo); the control technology of the driver is divided into frequency conversion control and servo control according to the characteristics of the motor; the common types of oil pumps are gear pumps, plunger pumps, vane pumps, and gear pumps include external Gears, internal gears and helical type.

In addition to the above three standard components, the servo control system still needs the following accessories:

1. The control card (ControlCard) is sometimes called the PG card, which is used for the communication and conversion of the communication interface, so that the encoder signal is fed back to the card for vector control of the speed.

2. The encoder transmission line (Encoder) transmits the signal of each terminal on the encoder to the driver side, and the driver side usually uses 9pinD-sub as the communication interface.

3.BreakResistance, also known as braking resistor or pick-up resistor, avoids the current generated by the motor reversal when the motor turns and stops suddenly from being directly recharged to the driver end, causing the driver to burn out, and the braking resistor will consume this back-charging flow. Let it go hot.Technology has been developed to store and reuse the electricity of the rechargeable current, which is a big progress in saving energy.

Main Features:

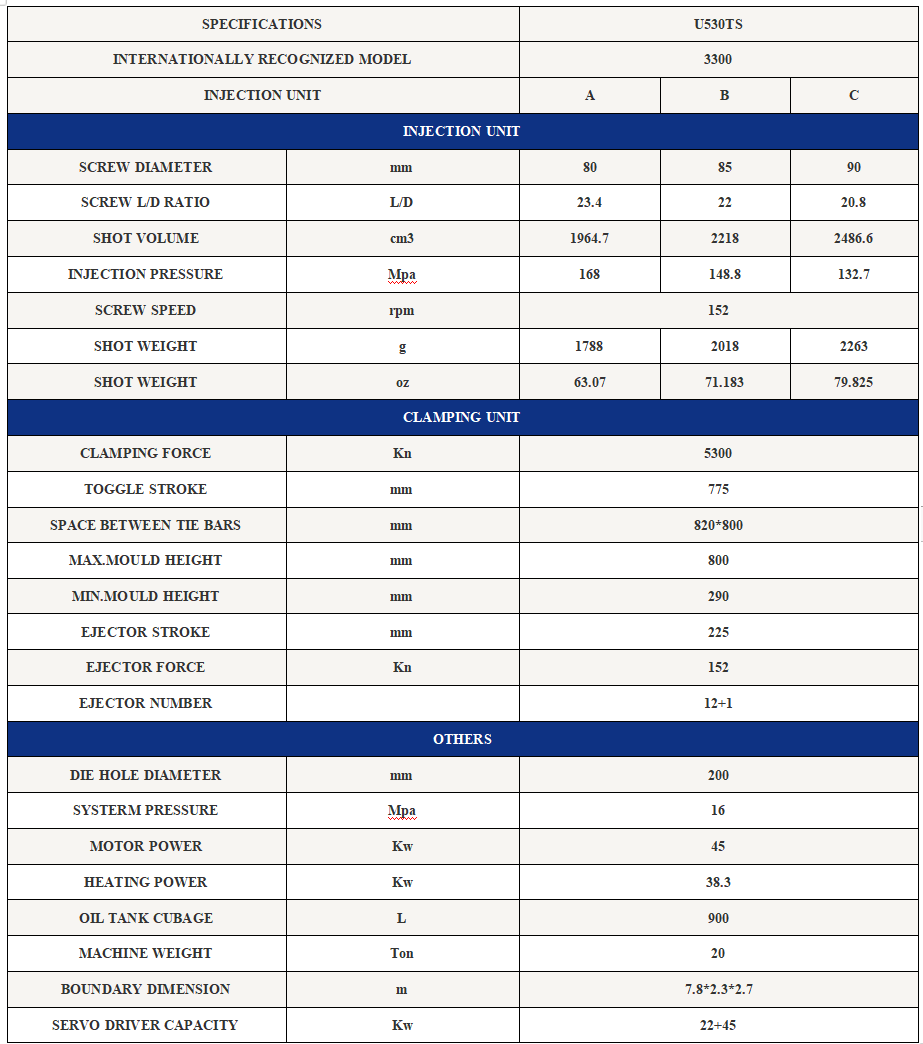

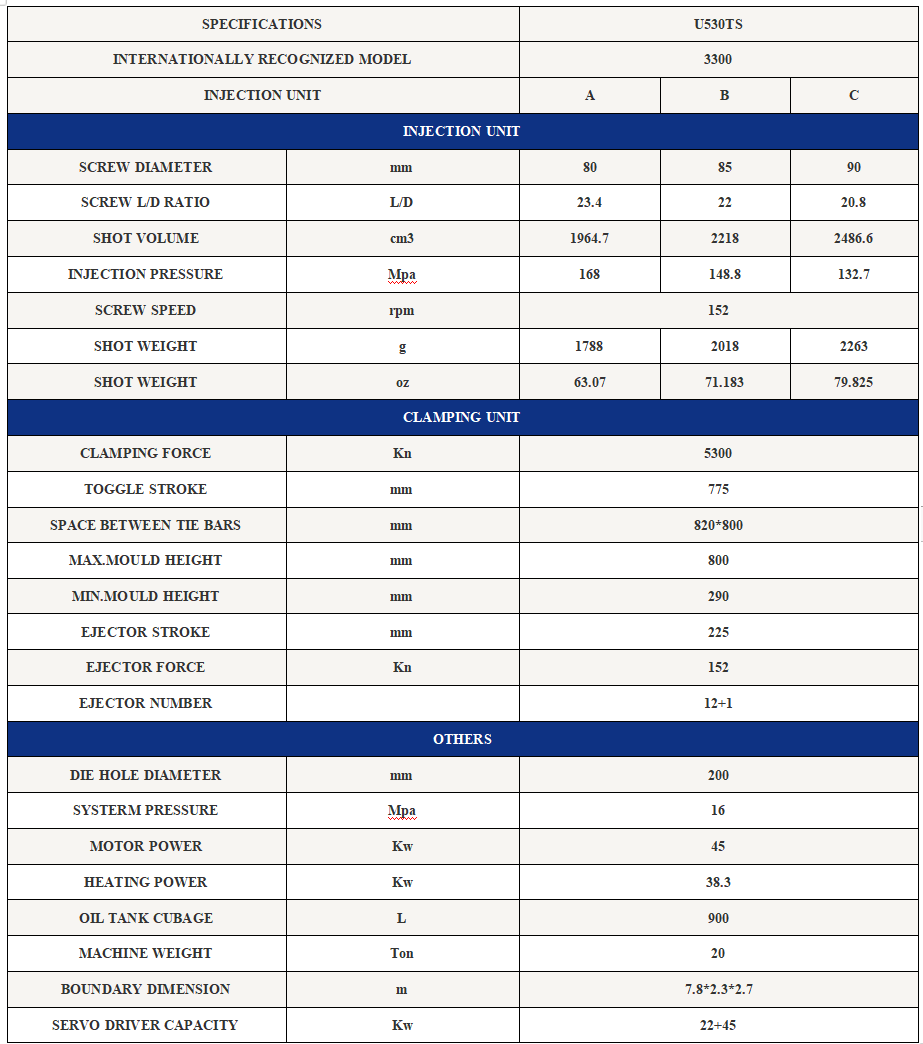

One.The Lock Section

1.Arch template, effectively protects the mould, especially suitable for big template with small mold.

2.The electric ruler is installed on the crosshead, the position is more precise.

3.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly

4.The connected tail-board stills itself with big lock shaft, improves tail-board strength, and ensures zero abrasion of the tail-board, easy for maintenance.

5.Connected movable plate, improves its rigidity and reduces deformation

6.Connected thrust bearing, improves its strength and stills itself with small lock shaft, ensures zero abrasion.

7.Arch template fully complies with mechanical property, largely improves template strength.

8.More reasonable toggle design, speeds and stabilizes mold opening and closing.

9.Adjustable movable plate mounting plate, makes the installation easier.

10.Mixed design of T-shape groove and die hole, increases universality of the mold.

Two.The Injection Section.

1.Bridge type support, improves injection smoothness.

2.Longer length-diameter ratio screw design, improves plasticizing effect.

3.Double seal structure, ensures no oil leakage.

4.Withhold type press plate, easy for debugging and assembly.

5.Bijection structure, improves stability.