Plastic trash can injection mould

For investors, a qualified trash can mold is crucial. In order to produce high-quality sorted trash cans, we must start with the quality of the mold and carry out strict size processing and quality control.

The following is a list of key points for you to manufacture sorting trash can molds for your reference and study:

● Short injection molding cycle, high output per unit time

The CAE software is used to analyze the temperature distribution during the molding process, and the design of the cooling system is strengthened at the highest temperature, so as to balance the cooling water layout, effectively shorten the cooling time, and speed up the cycle.

● The molding system has strong stability and high yield

The design of the runner system is reasonable, the yield is high, and the hot runner adopts German heating elements, which is balanced and stable.

● The wall thickness of the product is uniform, not eccentric, and the mold life is long

The trash can mold has precise assembly, high dimensional accuracy, strict quality control, and reasonable design of the clamping guide mechanism.

● Suitable for low melt fat number (MFI) plastic injection molding, the product is durable

The mold strength is good, the force is balanced, the pressure of the molding system is low, and it is suitable for low melting index plastic injection molding. The product has strong toughness, drop resistance and aging resistance.

With many years of experience in the manufacture of sorting trash can molds, Shouli not only knows the design points and can flexibly apply them to the design, so you can get the most comprehensive mold manufacturing services here.

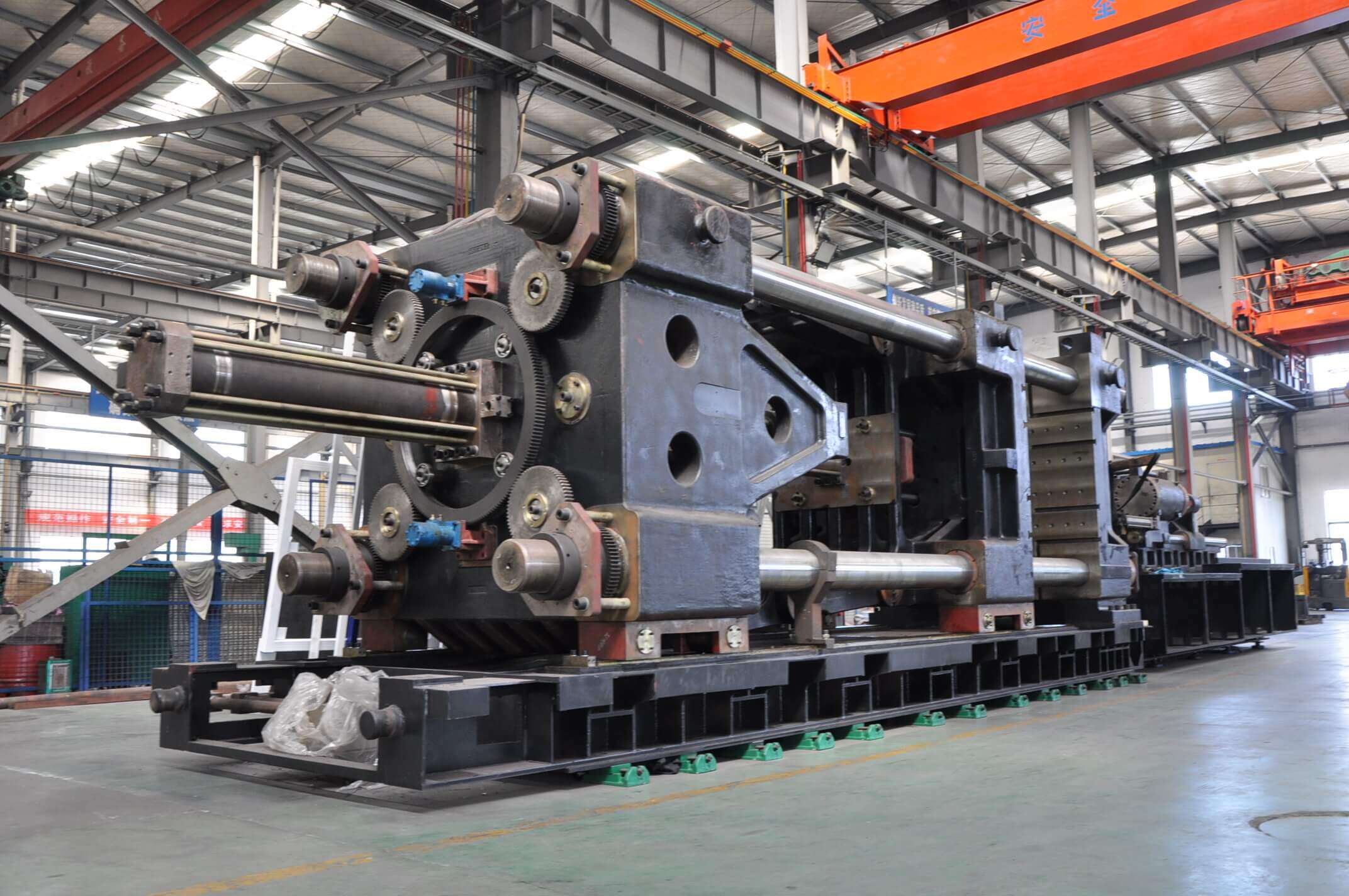

Sorting trash can injection molding production line service

Sino is committed to providing customers with the most comprehensive sorting trash can injection molding production line services. Below I will briefly list a few points for you.

● Conduct a comprehensive review of the entire sorting trash can production line

Before the project starts, the technical team will conduct preliminary analysis based on your needs, relying on the company's mold production process and previous production experience, and put forward feasible improvement suggestions for the analysis results.

● Budget analysis of sorting trash can molding project

● Sorting trash can product design

We can draw it for you by a team of professional engineers.

● Sorting trash can mould design

Provide mold modeling drawing with humanized and optimized design

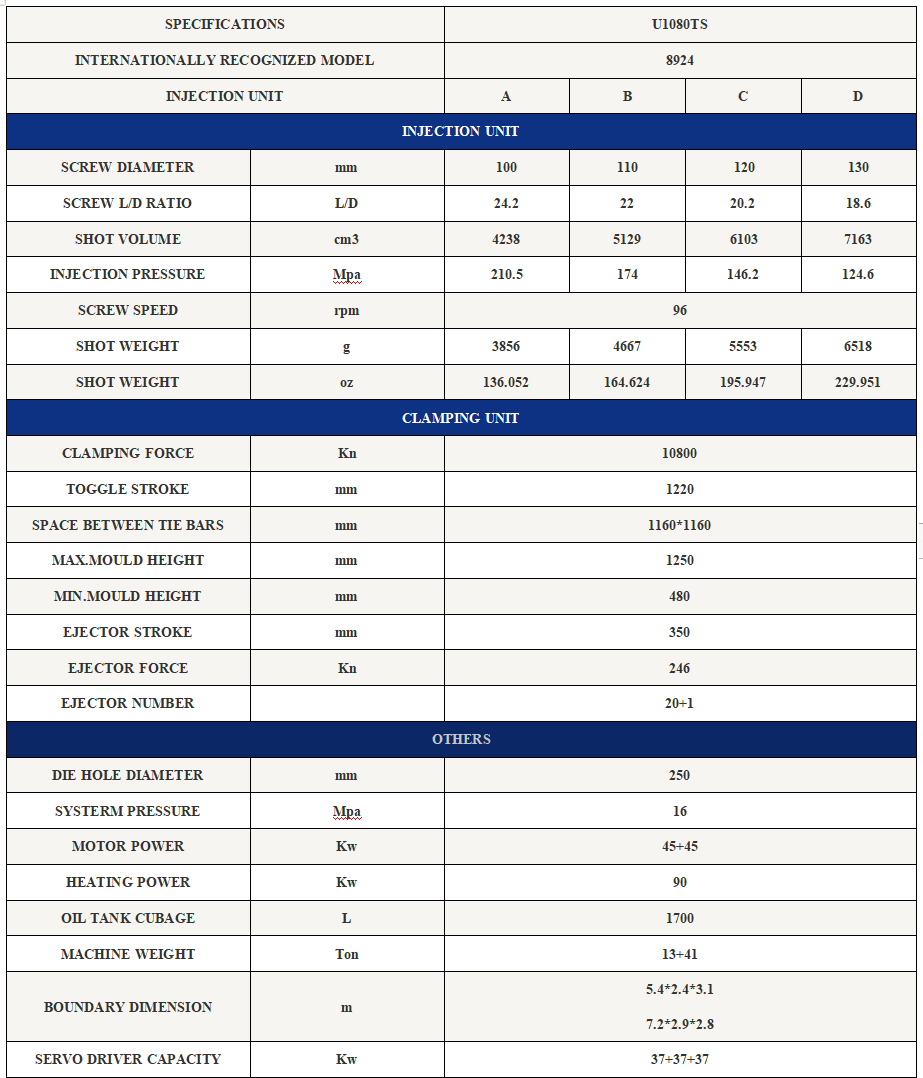

● Choose the most suitable machine

Equipped with the most suitable model according to the customer's budget and the actual needs of sorting trash can molds.

● Factory layout

We can provide professional injection molding workshop layout planning, water, gas, circuit layout, auxiliary machines, driving.You can get a complete injection molding workshop planning plan and put it into construction in the shortest time.

● Install wiring at customer's factory and provide worker operation training

After the machines and molds are shipped to your factory, we can dispatch engineers to perform on-site installation and commissioning and provide training on machine operation and maintenance according to your needs.

● Provide all technical drawing support and high-quality after-sales service

Helps customers to easily maintain sorting bin molds and injection molding machines.