The necessary factors to consider in the injection molding process are worthy of collection!

Thermal performance and cooling rate

1. Various plastics have different thermal properties such as specific heat, thermal conductivity, and thermal deformation temperature. When plasticizing with a high specific heat, a large amount of heat is required, and an injection molding machine with a large plasticizing capacity should be selected. The cooling time of plastics with high heat distortion temperature can be short and demoulding is early, but cooling deformation should be prevented after demoulding.

Plastics with low thermal conductivity have a slow cooling rate (such as ionic polymers, etc.), so they must be fully cooled to enhance the cooling effect of the mold. Hot runner molds are suitable for plastics with low specific heat and high thermal conductivity. Plastics with large specific heat, low thermal conductivity, low thermal deformation temperature and slow cooling rate are not conducive to high-speed molding. Appropriate injection molding machines must be selected and mold cooling must be strengthened.

2. Various plastics are required to maintain an appropriate cooling rate according to their types and characteristics and the shape of plastic parts. Therefore, the mold must be equipped with a heating and cooling system according to the molding requirements to maintain a certain mold temperature. When the material temperature increases the mold temperature, it should be cooled to prevent the plastic parts from being deformed after demoulding, shorten the molding cycle, and reduce the crystallinity.

When the plastic waste heat is not enough to keep the mold at a certain temperature, the mold should be equipped with a heating system to keep the mold at a certain temperature to control the cooling rate, ensure fluidity, improve filling conditions or control the plastic parts to cool slowly. Prevent uneven cooling inside and outside of thick-walled plastic parts and improve crystallinity.

For those with good fluidity, large molding area and uneven material temperature, according to the molding conditions of plastic parts, heating or cooling is sometimes used alternately, or local heating and cooling are used together. For this purpose, the mold should be equipped with a corresponding cooling or heating system.

Hygroscopic

There are various additives in plastics, which make them have different degrees of affinity for water. Therefore, plastics can be roughly divided into two types: hygroscopic, adhering to water, and non-absorbent and not easy to adhere to water. The water content in the material must be controlled within the allowable range. Otherwise, under high temperature and high pressure, water will become gas or hydrolysis will occur, which will cause resin foaming, decreased fluidity, poor appearance and mechanical properties.

Therefore, hygroscopic plastics must be preheated by appropriate heating methods and specifications as required to prevent re-hygroscopicity during use.

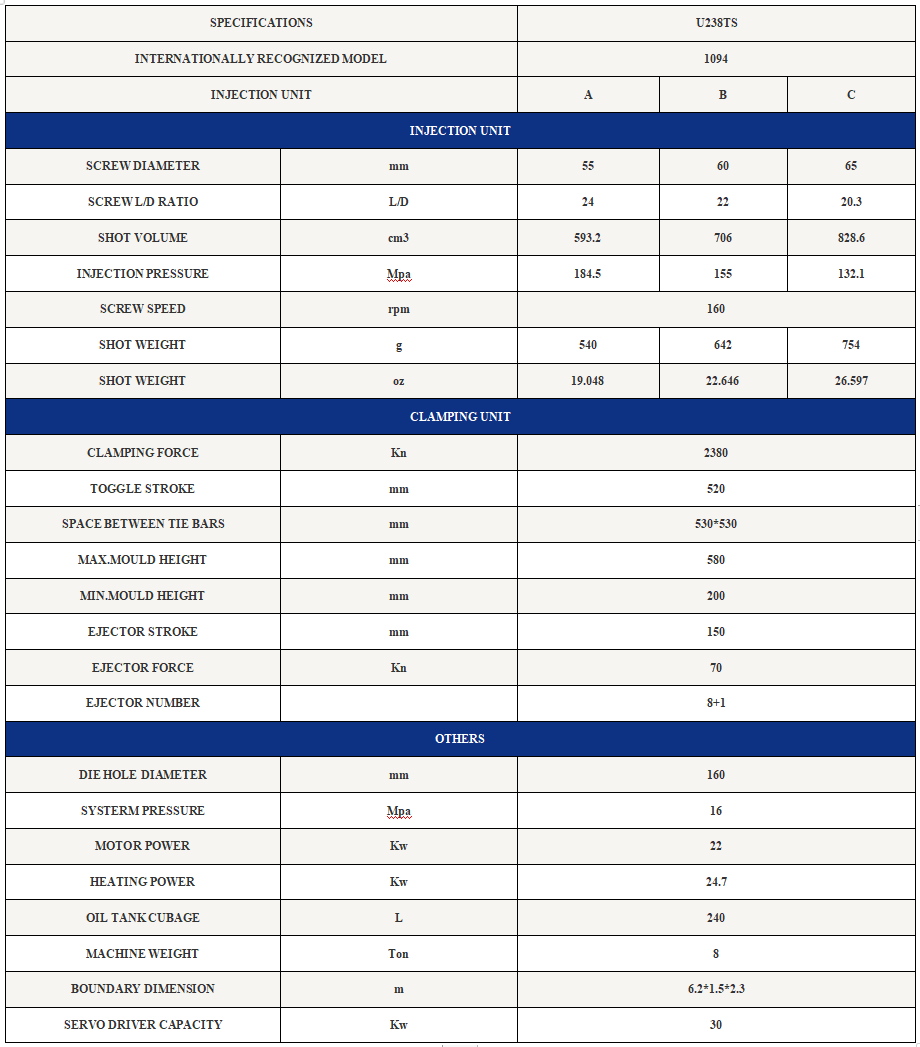

Main Features:

One.The Lock Section

1.Arch template, effectively protects the mould, especially suitable for big template with small mold.

2.The electric ruler is installed on the crosshead, the position is more precise.

3.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly

4.The connected tail-board stills itself with big lock shaft, improves tail-board strength, and ensures zero abrasion of the tail-board, easy for maintenance.

5.Connected movable plate, improves its rigidity and reduces deformation

6.Connected thrust bearing, improves its strength and stills itself with small lock shaft, ensures zero abrasion.

7.Arch template fully complies with mechanical property, largely improves template strength.

8.More reasonable toggle design, speeds and stabilizes mold opening and closing.

9.Adjustable movable plate mounting plate, makes the installation easier.

10.Mixed design of T-shape groove and die hole, increases universality of the mold.

Two.The Injection Section.

1.Bridge type support, improves injection smoothness.

2.Longer length-diameter ratio screw design, improves plasticizing effect.

3.Double seal structure, ensures no oil leakage.

4.Withhold type press plate, easy for debugging and assembly.

5.Bijection structure, improves stability.