1.Increasing the injection pressure can improve the tensile strength of PP injection molded parts

PP material is more elastic than other hard compounds, so the density of injection molded parts will increase with the increase of pressure. This characteristic is relatively obvious. When the density of plastic parts increases, its tensile strength will naturally increase, and vice versa.

However, when the density increases to the maximum value that PP itself can achieve, and then increasing the pressure, the tensile strength will not continue to increase, but will increase the residual internal stress of the injection molded parts, making the injection molded parts brittle, so it should be stopped in moderation.

Other materials have a similar situation, but the apparent degree will be different.

2.The hot oil injection molding of the mold can improve the strength of the steel parts and nylon parts

Nylon and POM materials are both crystalline plastics. The mold is injected with hot oil by a hot oil machine, which can slow down the cooling rate of the injection molded parts and improve the crystallinity of the plastic. At the same time, due to the slowing down of the cooling rate, the residual internal stress of the injection molded parts is also reduced. Therefore, the impact resistance and tensile strength of nylon and POM parts injected with hot oil will be improved accordingly.

It should be noted that the size of nylon and POM parts injected with hot oil transported by hot oil machine will be slightly different from that of injection molded parts with water transport, and the nylon parts may be larger.

3.The glue melting speed is too fast, even if 180 ℃ injection molding will produce glue

Under normal circumstances, the pvc 90 degree material is injected at 180 ℃, the temperature is sufficient, and generally there is no problem of raw rubber. However, it is often due to the reasons that the operator did not pay attention, or intentionally accelerated the melting speed in order to speed up production, so that the speed of the screw retreat is quite fast. More than one-third of the position, the time for the PVC material to be heated and stirred is seriously insufficient, resulting in the problem of melt temperature and uneven mixing of raw rubber, which makes the strength and toughness of the injection molded parts quite poor.

Therefore, when injecting PVC material, be careful not to arbitrarily adjust the melt speed to more than 100 rpm. If it must be adjusted very quickly, remember to increase the temperature of the material by 5 to 10 °C, or appropriately increase the back pressure of the melt to match. cause heavy losses.

Regarding this issue, because most people do not care too much, it is specially raised here to remind you that you must pay attention during production, and remember to do a good job in inspection.

On the contrary, it should be noted that if the melting speed is too slow, even if it is a 180-degree injection of PVC with a temperature of 90 degrees, it will cause the problem of glue burning, especially for transparent PVC, there will be many black spots and air lines on the injection-molded parts.

Main Features:

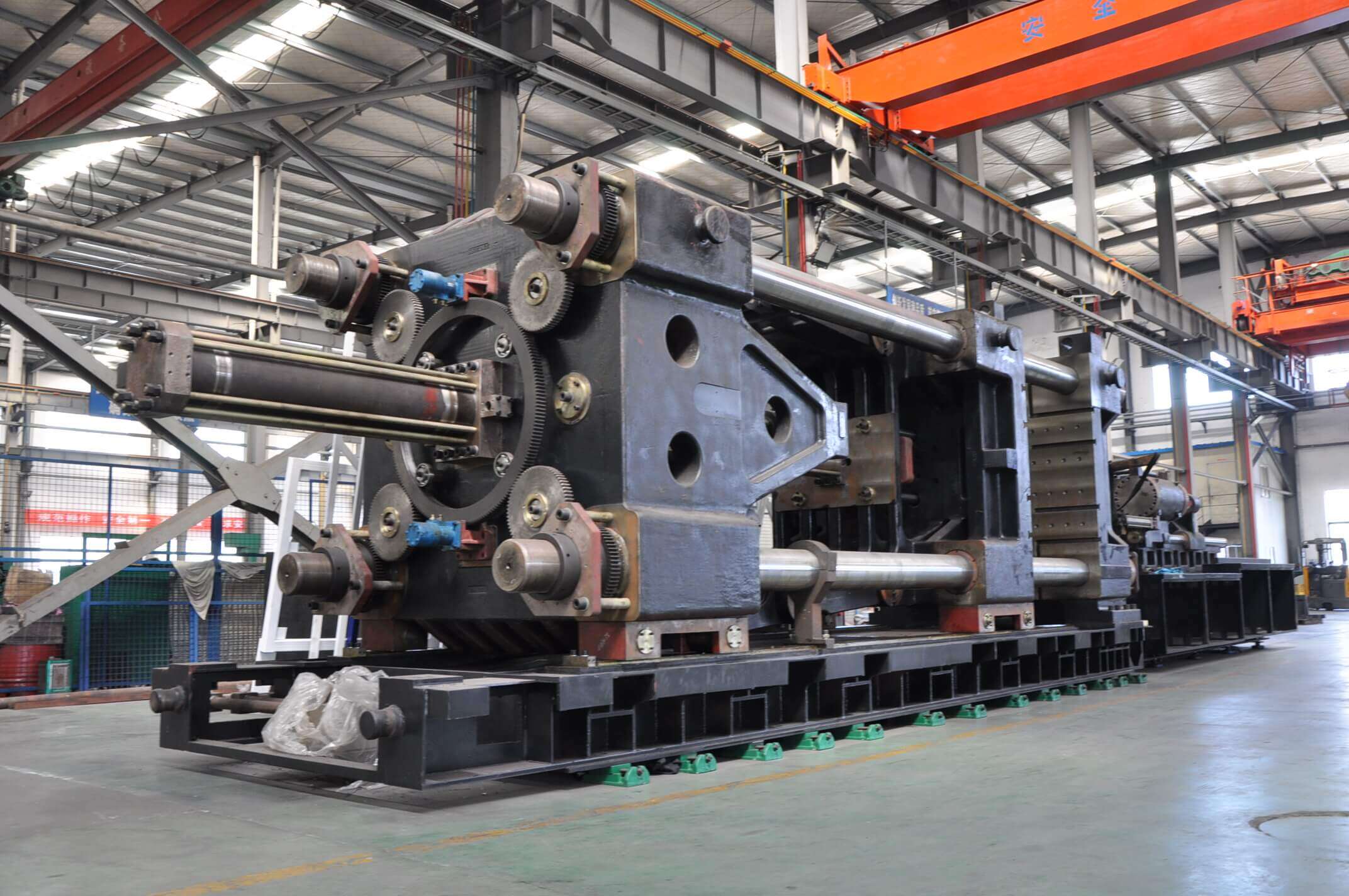

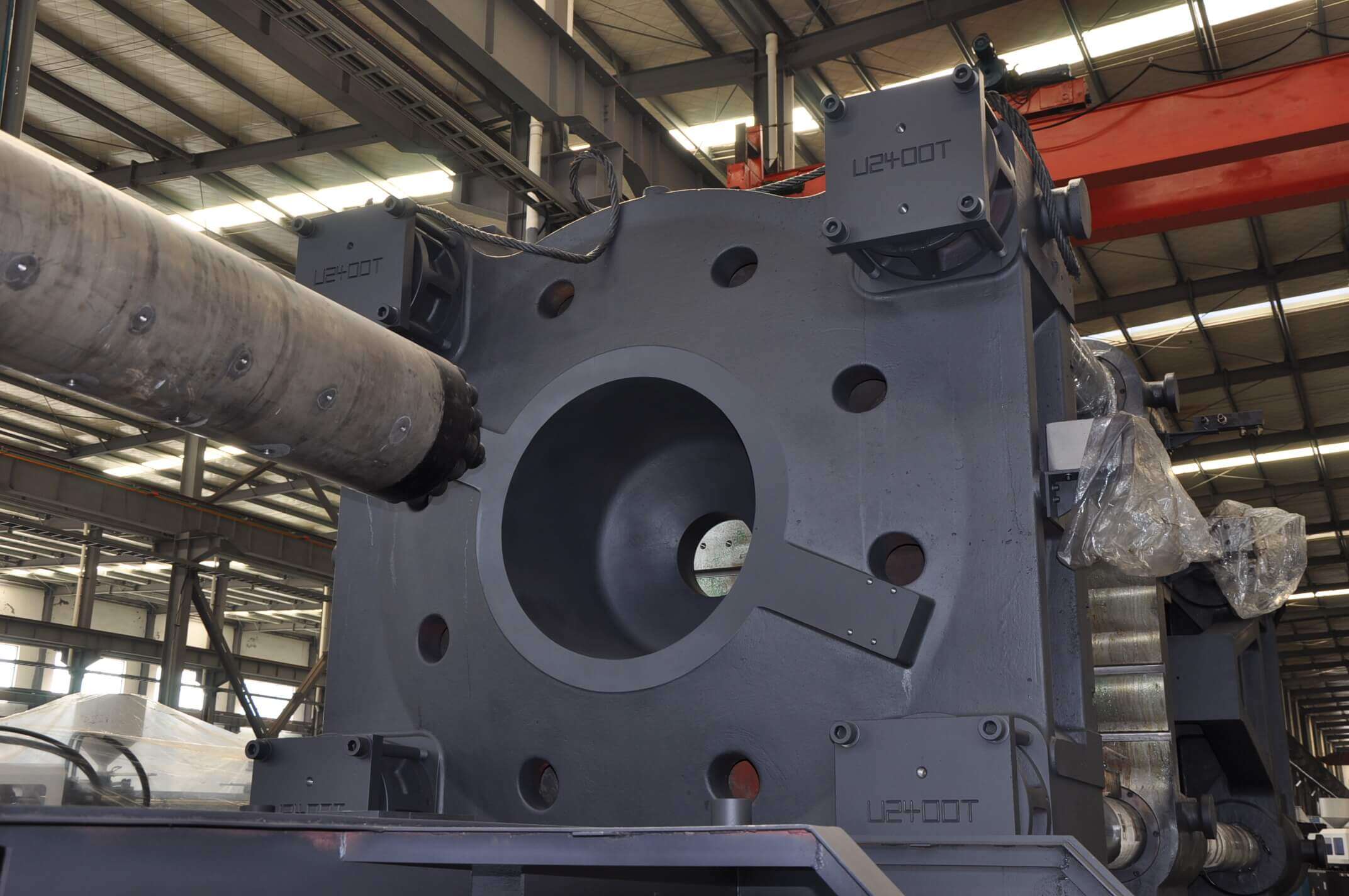

One.The Lock Section

1.Arch template, effectively protects the mould, especially suitable for big template with small mold.

2.The electric ruler is installed on the crosshead, the position is more precise.

3.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly

4.The connected tail-board stills itself with big lock shaft, improves tail-board strength, and ensures zero abrasion of the tail-board, easy for maintenance.

5.Connected movable plate, improves its rigidity and reduces deformation

6.Connected thrust bearing, improves its strength and stills itself with small lock shaft, ensures zero abrasion.

7.Arch template fully complies with mechanical property, largely improves template strength.

8.More reasonable toggle design, speeds and stabilizes mold opening and closing.

9.Adjustable movable plate mounting plate, makes the installation easier.

10.Mixed design of T-shape groove and die hole, increases universality of the mold.

Two.The Injection Section.

1.Bridge type support, improves injection smoothness.

2.Longer length-diameter ratio screw design, improves plasticizing effect.

3.Double seal structure, ensures no oil leakage.

4.Withhold type press plate, easy for debugging and assembly.

5.Bijection structure, improves stability.