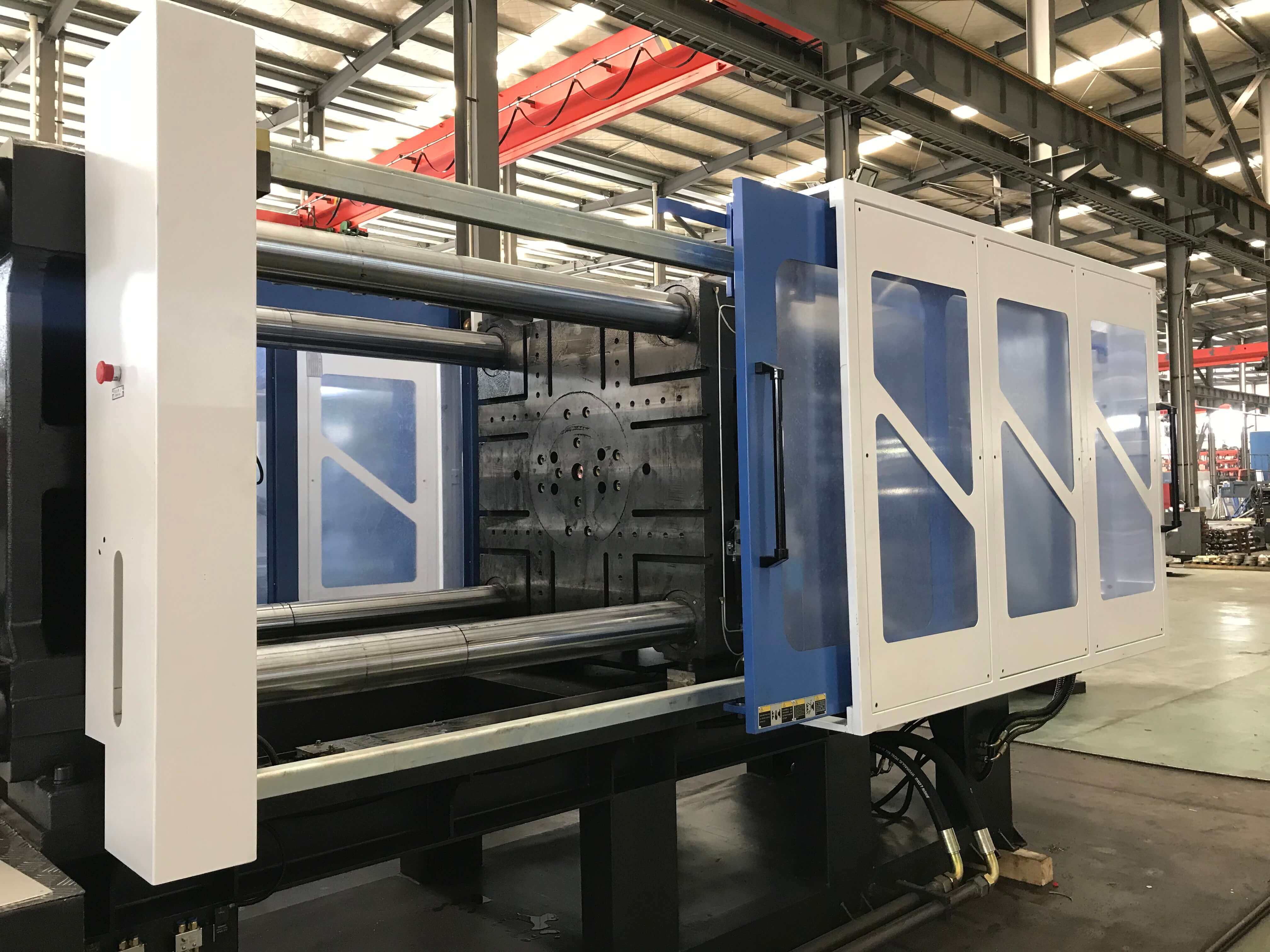

In the era of rapid development of science and technology, the use of servo injection molding machines is increasing. Its working principle is similar to that of injection syringes. It uses the thrust of the screw to inject the plasticized molten plastic into the closed mold. In the cavity, the process of obtaining the product after curing and shaping. The injection molding of the servo injection molding machine is a cyclic process. Each cycle mainly includes quantitative feeding - melting and plasticizing - pressure injection - mold filling and cooling - mold opening and removal. After the plastic parts are taken out, the mold is closed again for the next cycle.

Today, I will briefly tell you how to choose a servo injection molding machine.

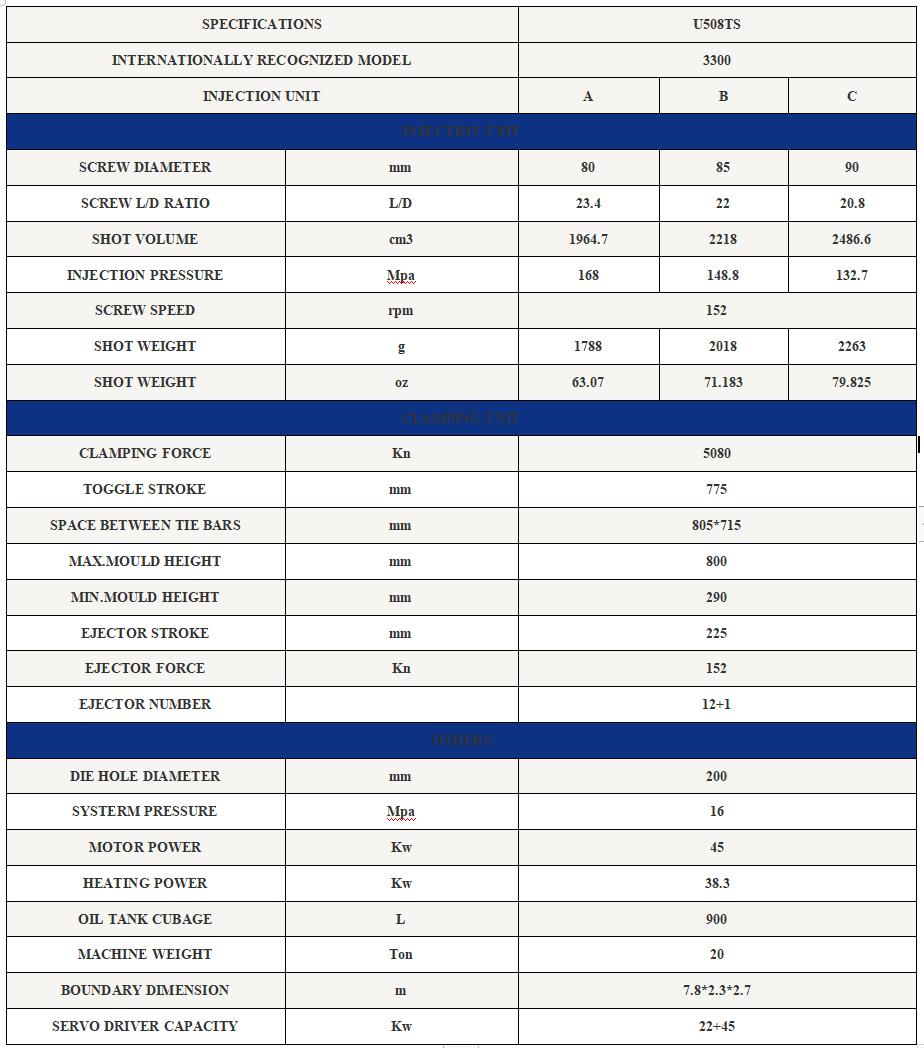

1. Specifications and models

The key comparison data in the specifications and models include the proportional relationship between the mass (or volume) and external dimensions of the injection molded products of the servo injection molding machine and the parameter values in the equipment, that is, the mass (weight) of the product and the theoretical injection volume (or volume) of the servo injection molding machine. The proportional relationship between: the size requirements between the length (height) of the product and the thickness of the forming mold (the thickness of the mold on the moving template) and the travel distance of the moving template of the servo injection molding machine.

In addition, it should be verified that the mold structure size to be installed on the servo injection molding machine is consistent with the conditions of the servo injection molding machine:

1. The spacing of the tie rods should be larger than the width and height of the mold to facilitate the assembly of the mold;

2. The size of the template meets the size requirements when the forming mold is installed and fixed;

3. The width and height of the mold must conform to the small mold size recommended by the injection molding machine.

2. Volume modulus

It is a larger plastic mold size that can fit.

3. The amount of melt

The large amount of glue that can be injected from the barrel at one time should not exceed 70% of the total molten glue amount of a molded product.

4. Clamping force

Referring to the surface area of the product, the clamping force of the mold cannot be opened when the injection pressure is high.

Whether the type and specification of the servo injection molding machine are correctly selected before use has a great impact on the production cost, quality and production efficiency of the injection molding products of the servo injection molding machine. This article mainly describes how to buy a servo injection molding machine. I hope you will have a better understanding of the servo injection molding machine through this article.