The thought of mold design is very important to make the mold perfect

How to produce a good product mainly has the several factors:

(1) raw material product

(2) for the optimization design of the mould

(3) for the optimization design of the injection molding process, but a good mould for mould compared with a pair of mold with poor, have 3-5 production efficiency, to create a pair of good mold mold (high efficiency) mainly depends on these points: (1) mold material (2) process (3) computer aided system (4) new processing equipment (5) mold design and design ideas, the fifth point is the most important.

The best design

Each product has several kinds of design scheme, but that kind of design scheme for the product, which requires the designer's abundant practical experience, a good design, involves, consideration to all aspects, such as the characteristics of plastic (all kinds of different plastic, mold design is different), the structure of the product complexity, process parameters of injection molding machine, Die steel screening, mold fastness, etc. For example, connectors of electronic products, plastic nylon material, nylon activity is very strong, with high requirements for the mold, in the mold design scheme, moving mold can not be demoulded by plane structure. For example, for plastic with strong corrosion, corrosion resistant die steel and so on.

Spatial simulation and imagination

Mold designers, have a strong space imagination ability than ordinary people (space logical ability), that is, a product in hand, can come up with a variety of design schemes.To find out an optimal design, first of all, should design a variety of design schemes, comparison and screening. To determine a more reasonable design scheme, then using simulation method of imagination, in the brain of a simulation that optimal design scheme of simulation in injection molding, the possible deficiency (can also be simulated in the computer, but computer simulations is not correct), list of possible topics, correcting in the redesign. Can reduce unnecessary waste, shorten the mold manufacturing time, improve the production efficiency,

Innovation consciousness

As a designer, has innovation consciousness, boldly put forward their own all kinds of design scheme of the continuous development and evolution, the technology is a new technology is in practice continuously evolved, really want to get a kind of new technology, to need to constantly explore in the production practice, as those who die mold expert's theory is not imaginary, Also get experience from practice, in the design of innovation, in the design to gather mold designers together to discuss and research, a person's strength is limited. Because mold design is the most critical!

Injection molding and surrounding knowledge

Injection molding, and mold testing and other influences on mold design is very large, this can not be ignored, especially when the mold testing, you can find many problems that are difficult to consider at the beginning of the design.

The maturity of a design scheme is a big factor. If the software foundation and processing knowledge are understood as skills, the practicality of mold manufacturing is the way. Everything we do is in the service of practicality.

Where is the utility?

Is the product good injection molding? Is there any other defects?How about the production cycle?

How can we improve this one? If let a design very understand injection molding, it is not realistic, injection molding this knowledge is very big. But the basic knowledge is to understand the common causes of some product defects, how to solve them.

More to try the mold, will be of great help, in the mold testing site encountered problems and solve, can improve a person's comprehensive ability.

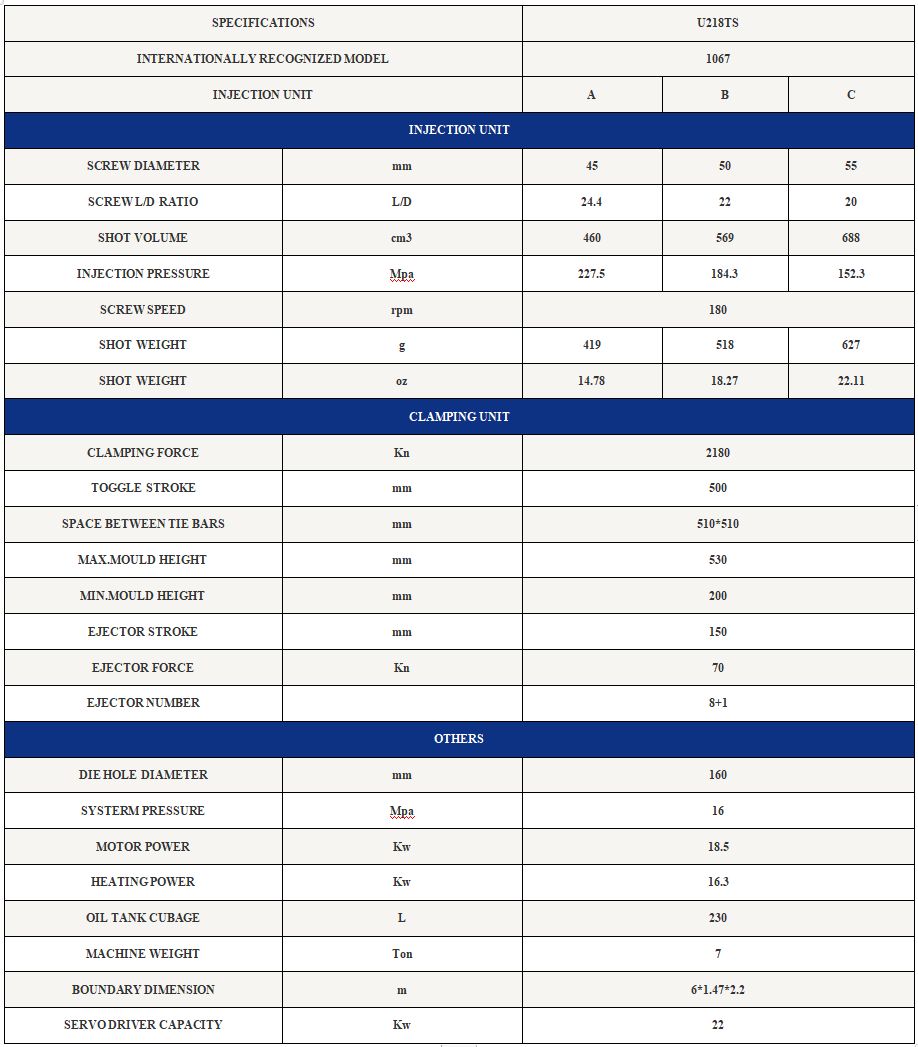

Main Features:

One.The Lock Section

1.Arch template, effectively protects the mould, especially suitable for big template with small mold.

2.The electric ruler is installed on the crosshead, the position is more precise.

3.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly

4.The connected tail-board stills itself with big lock shaft, improves tail-board strength, and ensures zero abrasion of the tail-board, easy for maintenance.

5.Connected movable plate, improves its rigidity and reduces deformation

6.Connected thrust bearing, improves its strength and stills itself with small lock shaft, ensures zero abrasion.

7.Arch template fully complies with mechanical property, largely improves template strength.

8.More reasonable toggle design, speeds and stabilizes mold opening and closing.

9.Adjustable movable plate mounting plate, makes the installation easier.

10.Mixed design of T-shape groove and die hole, increases universality of the mold.

Two.The Injection Section.

1.Bridge type support, improves injection smoothness.

2.Longer length-diameter ratio screw design, improves plasticizing effect.

3.Double seal structure, ensures no oil leakage.

4.Withhold type press plate, easy for debugging and assembly.

5.Bijection structure, improves stability.