Introduction of injection molding machine maintenance work

The core of maintenance of injection molding machine is fault judgment and fault treatment. It involves a wide range of knowledge, a large degree of complexity, with a certain depth (such as comprehensive professional knowledge level). It is necessary to have basic knowledge of mechanical equipment maintenance, basic knowledge of hydraulic maintenance and basic knowledge of electrical maintenance. In fact, the maintenance work of injection molding machine is hard, but it is also a process of continuous learning and progress. As long as you master the basic working principle and basic working methods of injection molding machine, no matter all kinds of models, all changes are inseparable from its root, you can explore a set of maintenance procedures to ensure the normal operation of injection molding machine.

Maintenance workers must first understand and master the contents of the operation manual of the injection molding machine, familiar with and master the mechanical parts, circuit and oil circuit of the injection molding machine, understand the working process of the machinery, circuit and oil circuit of the injection molding machine in normal operation, and understand and master the inspection and maintenance of electrical components and hydraulic components. Clear the normal working status and abnormal working status, to avoid time-consuming misjudgment and misassembly.

Maintenance work must understand the operation of equipment and have some basic knowledge of injection molding, and be able to use injection molding machine correctly. If you do not know how to operate the injection molding machine, maintenance work is very difficult, judging the fault may not be reliable. The circuit board and electrical components in the injection molding machine are affected by high temperature, environment, time and other factors for a long time, and the deviation of the working point of the components and the aging degree of the components are all within the normal range. Therefore, debugging injection molding machine is also one of the essential basic skills in maintenance work. It is very important to understand the working procedure of injection molding machine and debug the electronic circuit and hydraulic oil circuit of injection molding machine.

Maintenance work to be accurate, reliable and timely, it is necessary to study and master the contents of the operation manual of each type of injection molding machine. In the general maintenance process, the maintenance idea is usually circuit - oil road - mechanical parts action. And the adjustment work is carried out in reverse, such as mechanical action and clamping pressure is lack, you can go to find the oil circuit and circuit, such as the circuit output is normal, then adjust the oil valve.

If the oil works normally, adjust the electronic board of the circuit. Of course, the final adjustment, but the relationship between the three interdependent, mutual control. The correct use of instruments and meters, adjustment and detection circuit, maintenance of oil, debugging of the mechanical part of the position and action, is an important means to judge the fault.

General injection molding machine manufacturers only give the electrical block diagram of the equipment, the block diagram of the oil circuit and the main part of the machinery, which is not enough for maintenance work. Must pay attention to the daily maintenance work, collect, sort out all aspects of the relevant information. Such as electrical, electronic, mechanical spare parts, oil, electromagnetic valve and other information. For example, if there is an opportunity to map the electrical circuit schematic diagram, map the schematic diagram of the electronic board and the actual wiring diagram, and measure the device corresponding to the wiring terminal, so as to provide accurate detection point whereabouts for fault judgment and analysis in maintenance.

The specific parameters of the detection point were measured. When necessary, but also their own production of power supply, analog input and output signals, simulation test or adjustment, in order to master and obtain first-hand maintenance data, such as all levels of working point parameters.

The same is true for oil road maintenance, which must be adjusted and maintained comprehensively according to the characteristics of oil road and oil pressure solenoid valve. Often remove, clean, check, install the solenoid valve. These treatments are troublesome, but crucial.

Maintenance work must master and compiled in accordance with the principle, the logical system breakdown maintenance method and judgment process diagram, in combination with daily maintenance work reality, collect information related to the injection molding machine, such as fault, its method has gradually mature, simulation test, voltage test method, the on-off test method, circuit board replacement method and other methods. After repair, the working point should be readjusted, and the load test should be carried out to make the equipment work within the parameter range of the data listed in the operation manual.

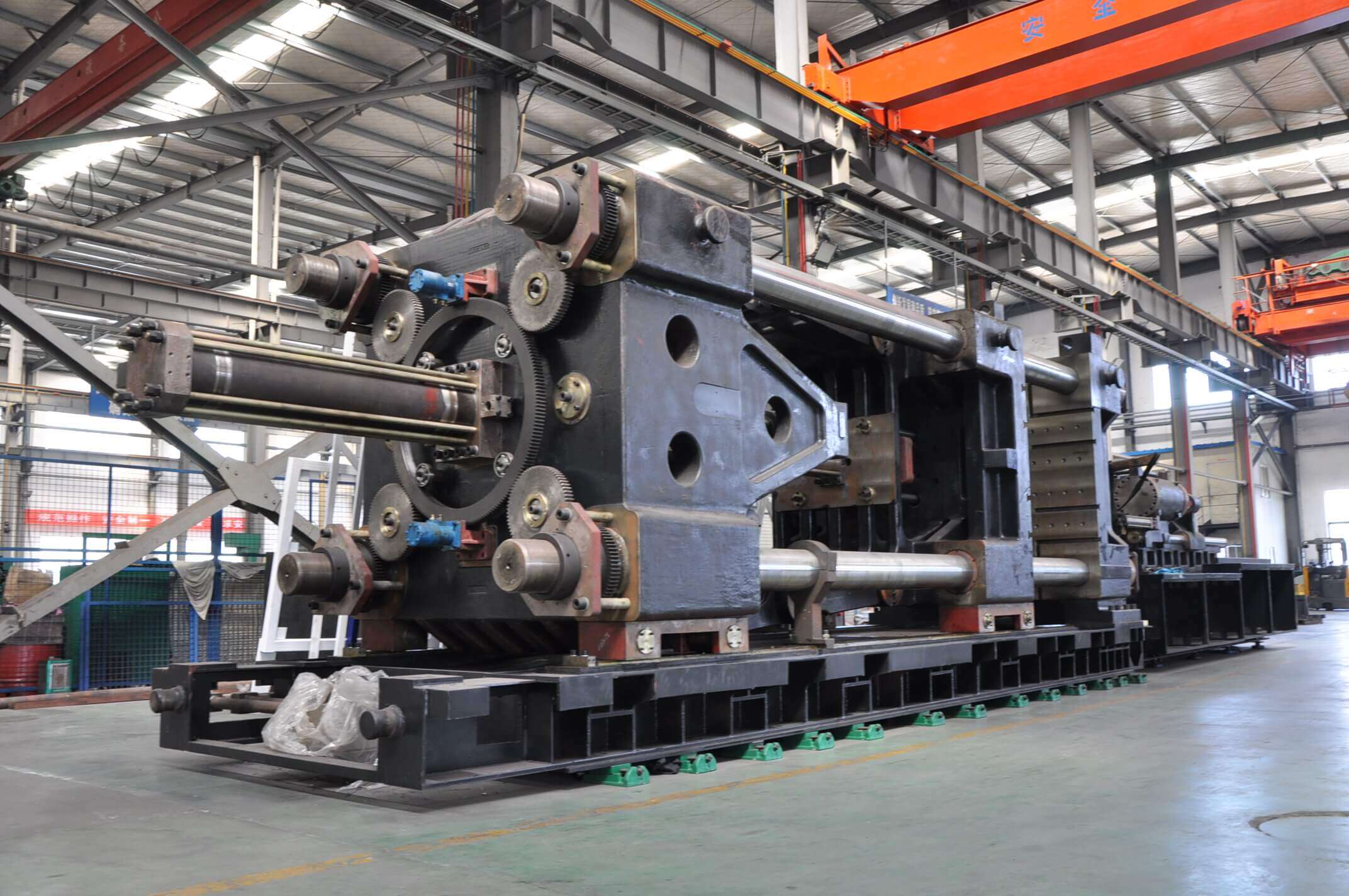

Main Features:

One.The Lock Section

1.Arch template, effectively protects the mould, especially suitable for big template with small mold.

2.The electric ruler is installed on the crosshead, the position is more precise.

3.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly

4.The connected tail-board stills itself with big lock shaft, improves tail-board strength, and ensures zero abrasion of the tail-board, easy for maintenance.

5.Connected movable plate, improves its rigidity and reduces deformation

6.Connected thrust bearing, improves its strength and stills itself with small lock shaft, ensures zero abrasion.

7.Arch template fully complies with mechanical property, largely improves template strength.

8.More reasonable toggle design, speeds and stabilizes mold opening and closing.

9.Adjustable movable plate mounting plate, makes the installation easier.

10.Mixed design of T-shape groove and die hole, increases universality of the mold.

Two.The Injection Section.

1.Bridge type support, improves injection smoothness.

2.Longer length-diameter ratio screw design, improves plasticizing effect.

3.Double seal structure, ensures no oil leakage.

4.Withhold type press plate, easy for debugging and assembly.

5.Bijection structure, improves stability.