The injection molding machine is a special plastic molding machine. It uses the thermoplasticity of plastic, and after being heated and melted, it flows into the mold cavity quickly with high pressure. After a period of pressure maintenance and cooling, it becomes a plastic product of various shapes.

The working cycle of the injection molding machine

Cooling and holding pressure: According to the setting of various pressures and time periods, the pressure of the barrel is maintained, and the cavity is cooled and formed at the same time.

Clamping the mold: The mold puller quickly approaches the fixed mold puller (including slow-fast-slow speed), and when it is confirmed that there is no foreign matter, the system turns to high pressure to lock the mold plate (maintain the pressure in the cylinder). The injection table moves forward: the injection table advances to the designated position (the nozzle is close to the mold).

Injection molding: The screw can be set to inject the molten material at the front end of the barrel into the mold cavity at multiple speeds, pressures and strokes.

Cooling and pre-molding: The products in the mold cavity continue to cool, while the hydraulic motor drives the screw to rotate to push the plastic particles forward, and the screw retreats under the control of the set back pressure. When the screw recedes to a predetermined position, the screw stops rotating, and the injection cylinder loosens back according to the setting, which is expected to end.

Electricity consumption of injection molding machine

The power consumption of the injection molding machine is mainly reflected in the following parts: the power consumption of the circulating cooling water pump, of which the power consumption of the hydraulic oil pump motor accounts for more than 80% of the power consumption of the entire injection molding machine, the power consumption of the hydraulic system oil pump, the power consumption of the heater. Therefore, reducing its power consumption is the key to energy saving of injection molding machines.

Precautions for starting the injection molding machine

When the machine is running, it is necessary to ensure that the hopper is properly installed and the raw materials are sufficient;

During the operation, the safety door must be closed, and the control box and power box must be closed at all times to prevent dust and impurities from entering the box;

Do not remove the protective cover of the melt tube at will to prevent burns and leakage, and do not stand on the protective cover of the melt tube during inspection;

It is strictly forbidden to operate the injection or melt glue operation before the temperature reaches the set electric heating temperature value, otherwise it will cause damage to the screw or oil pipe; the electric heating temperature is indicated by the two signal lights on the temperature controller. If the temperature is lower, the green light is on, continue to heat;

It is strictly forbidden to use manual injection under the condition of mold opening and when the shooting table has not been withdrawn, otherwise the fixed template fixing screw may be damaged and broken or the mold will fall off; it is also not allowed to manually control the shooting table to advance, otherwise the mold will also fall off;

It is strictly forbidden to clean the rubber material of the nozzle by hand. After the screw temperature rises, hands and face are not allowed to be close to the nozzle. Even if the injection does not start, the air pressure in the barrel can make the molten rubber spray from the nozzle to hurt people;

After using high-temperature decomposition or high-viscosity raw materials, the machine should be cleaned, and PE or PP rubber should be used, and low-pressure and low-speed operation should be selected to prevent the rubber from splashing and hurting people during cleaning;

For machines with a long downtime, it is necessary to withdraw from the shooting table and shoot out the extremely hot melt glue in the barrel, otherwise it is easy to break the glue or break the front, and the mold is also easy to be damaged.

To sum up

Sonly can not only provide injection molding machines with high safety, fast injection speed, high product molding accuracy, energy saving and environmental protection, but also provide you with an economical and reasonable one-stop solution for high-speed thin-walled plastic products, saving your Time and cost, let your products seize the market opportunity in the first time! If you have needs in this regard, you can contact us immediately and we will serve you wholeheartedly.

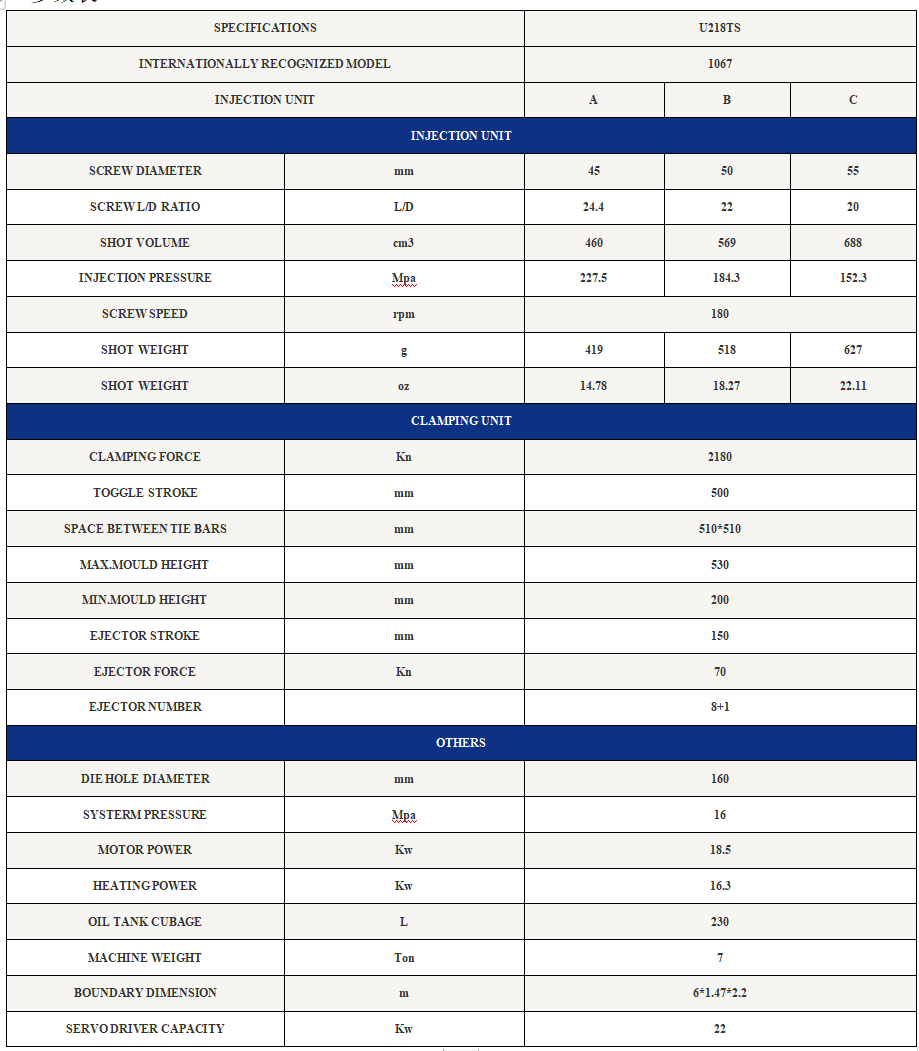

Main Features:

One.The Lock Section

1.Arch template, effectively protects the mould, especially suitable for big template with small mold.

2.The electric ruler is installed on the crosshead, the position is more precise.

3.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly

4.The connected tail-board stills itself with big lock shaft, improves tail-board strength, and ensures zero abrasion of the tail-board, easy for maintenance.

5.Connected movable plate, improves its rigidity and reduces deformation

6.Connected thrust bearing, improves its strength and stills itself with small lock shaft, ensures zero abrasion.

7.Arch template fully complies with mechanical property, largely improves template strength.

8.More reasonable toggle design, speeds and stabilizes mold opening and closing.

9.Adjustable movable plate mounting plate, makes the installation easier.

10.Mixed design of T-shape groove and die hole, increases universality of the mold.

Two.The Injection Section.

1.Bridge type support, improves injection smoothness.

2.Longer length-diameter ratio screw design, improves plasticizing effect.

3.Double seal structure, ensures no oil leakage.

4.Withhold type press plate, easy for debugging and assembly.

5.Bijection structure, improves stability.