Features of products:

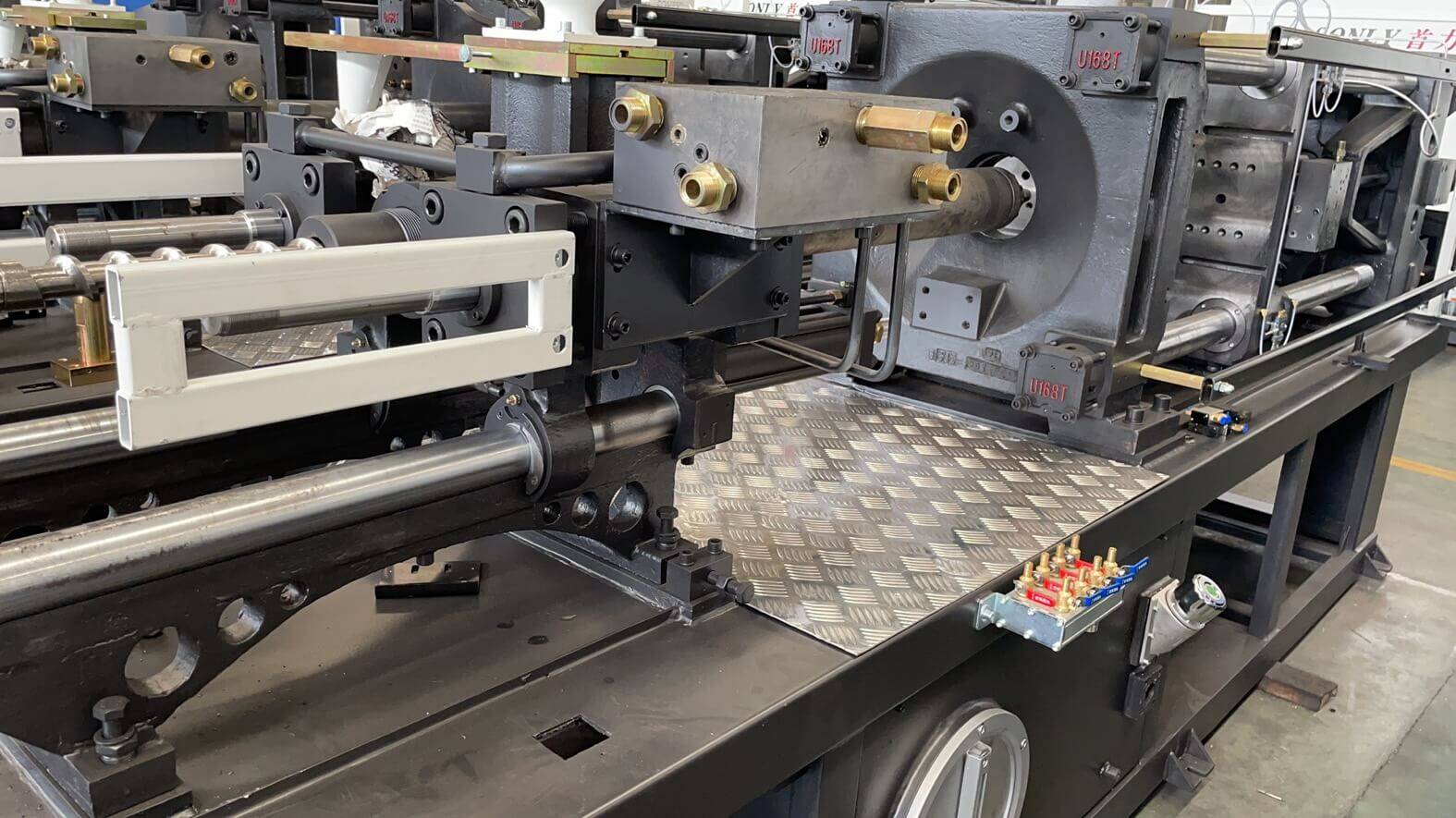

1.Hydraulic gear mold adjustment is stable and reliable;

2.The whole series of high-quality servo motors can save up to 70% of power and respond quickly;

3.High quality and durable ductile castings;

4.High-quality oil circuit structure, reliable and durable imported electrical accessories;

5.The latest generation of processing equipment, the accuracy is guaranteed;

6.The machine is fast and the sheet metal is beautiful;

7.A full range of T-slots for easy mold change.

How to ensure its quality?

Quality inspection method: Repeated injection accuracy is an important indicator of the stability of the injection molding machine. Generally speaking, it is the weight, size, and appearance of each product made by the same mold under the same process parameters during the injection molding process. The higher the repeatability, the better the stability of the injection molding machine.

Common fault classification and repair and maintenance methods

According to the degree of failure impact

Complete failure: it will cause the injection molding machine to completely lose its function.

Local failure: it will cause the loss of some functions of the injection molding machine.

According to the causes of failure

Abrasive failures: failures due to normal wear and tear of the injection molding machine.

Misuse faults: faults caused by incorrect operation and improper maintenance.

Inherent weakness failure: due to design problems, the injection molding machine has a weak link, and the failure occurs during normal use.

Gradual failure

This is caused by the gradual deterioration of the initial performance of the injection molding machine, and most of the failures of the injection molding machine belong to this type of failure. Such faults are closely related to the wear, corrosion, fatigue and creep of electronic control and hydraulic machinery components.

Sudden failure

This is caused by the combined action of various unfavorable factors and accidental external influences, which are beyond the limit that the injection molding machine can bear. For example: the screw is broken due to the overload of the barrel entering the iron material; the electronic board of the injection molding machine is broken down due to the high pressure intrusion. Such failures often occur suddenly and without prior warning.

Sudden failures mostly occur in the use stage of injection molding machines, often due to defects in design, manufacturing, assembly, and materials, or operational errors and illegal operations.

Intermittent failure

The injection molding machine loses some of its functions in a short period of time, and it can be restored after a little repair and debugging, without the need to replace parts.

Permanent failure

Some parts of the injection molding machine are damaged and need to be replaced or repaired to return to service.

Some maintenance methods

Electrical system: When checking the high-voltage parts of the machine, do not turn on the main power unless necessary. The cooling water cannot flow into the control box when changing the mold. When replacing the relay, the specified voltage relay should be used.

Oil pressure system: The pressure oil should be replaced every 3-4 thousand hours, and should not be mixed with new and old oil.

Injection parts: Keep the injection guide rod lubricated and clean, keep the surface of the nozzle clean and dry, and do not put anything into the hopper except plastics, pigments and additives.