How to prevent injection mold cooling water leakage

Injection mold cooling water leakage often occurs for many reasons, mainly in the following aspects:

1. The most common occurrence is at the joint of the cooling water pipe of the mold. If water leakage is found, a sealing tape should be wrapped around the thread of the pipe joint and then tightened.

2. Due to long-term molding conditions, the waterproof ring in the mold will be damaged, and the O-shaped waterproof rubber ring is easy to harden and crack, resulting in water leakage. Poor installation of some waterproof rings can also cause seal failure. Generally, the installation position and sealing performance of the sealing ring should be checked regularly.

3. The hole wall of the cooling water hole is damaged. This often happens when trying out a new mold, where the designed wall thickness is adequate, but the hole wall is broken due to machining errors or post-processing. In most cases, leaking water holes can no longer be used.

4. Maintenance of cooling water holes. It is easy to form scale in the cooling water hole, which hinders heat transfer, and in severe cases, the water channel is blocked, and regular maintenance is required. For straight water holes, insert a steel rod 0.5mm smaller than the diameter of the cooling water holes, and tap with a hammer to remove scale and rust. For the cooling water pipe embedded in the mold, the mold should be decomposed to remove the rust.

After the overhaul, a water leakage test should be carried out, and a hand pump should be used to fill the water hole with water, and keep it under 2MPa pressure for 5 minutes, and judge whether the water hole is leaking by observing whether the water pressure decreases. The water leakage can be blocked with elastic materials such as rubber and cork by mechanical fastening, and room temperature curing silica gel can also be used as the blocking material.

5. Regular maintenance and utilization of heating pipes and decompression pumps. The heating tube is an effective heat transfer element and is very effective for core cooling of thin and deep structures. In the parts where the cooling water is easy to pass, setting up a one-way heating pipe can reduce water leakage. In addition, using a decompression pump to suck cooling water is also a method to prevent cooling water leakage.

Main Features:

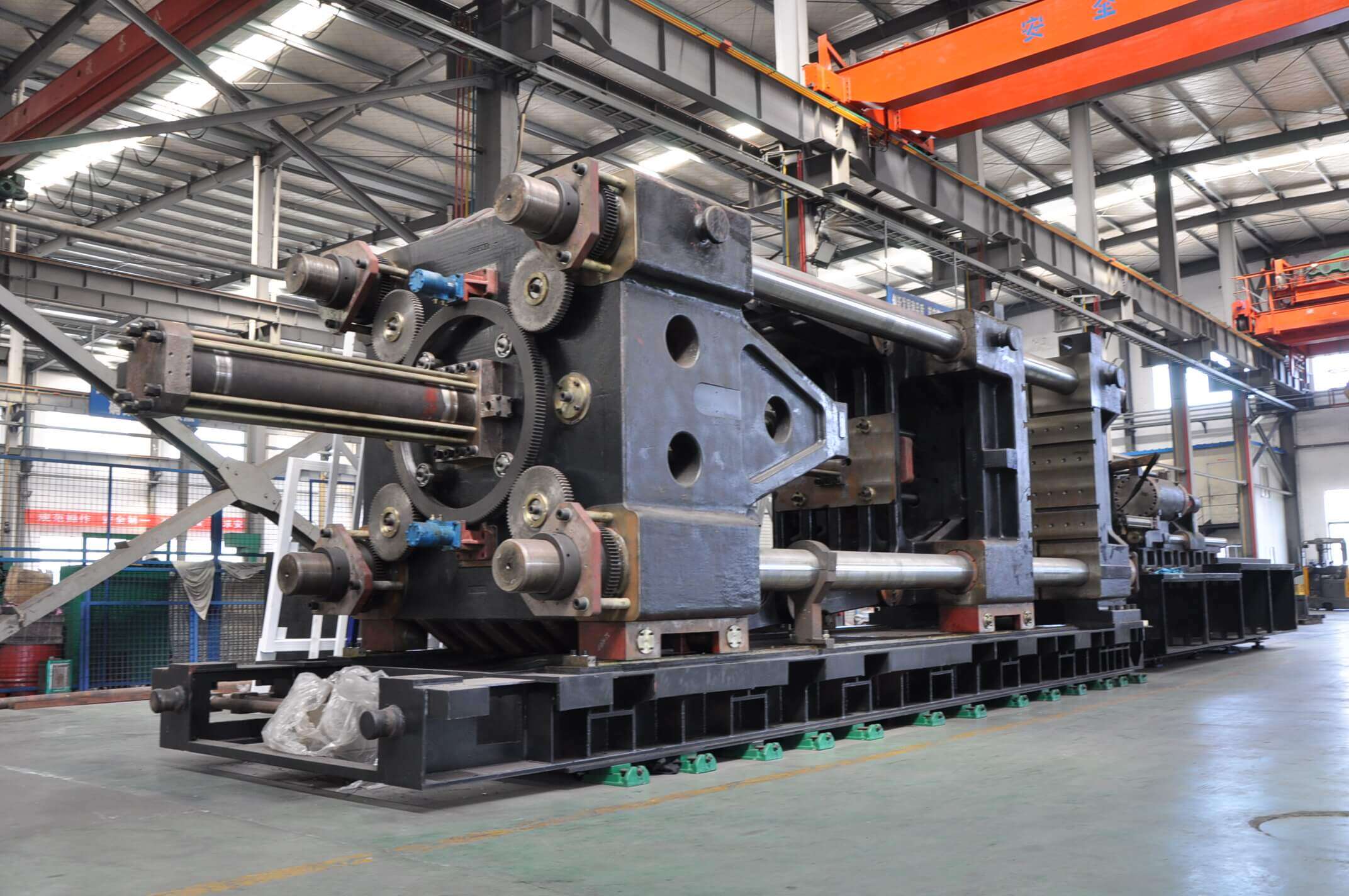

One.The Lock Section

1.Arch template, effectively protects the mould, especially suitable for big template with small mold.

2.The electric ruler is installed on the crosshead, the position is more precise.

3.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly

4.The connected tail-board stills itself with big lock shaft, improves tail-board strength, and ensures zero abrasion of the tail-board, easy for maintenance.

5.Connected movable plate, improves its rigidity and reduces deformation

6.Connected thrust bearing, improves its strength and stills itself with small lock shaft, ensures zero abrasion.

7.Arch template fully complies with mechanical property, largely improves template strength.

8.More reasonable toggle design, speeds and stabilizes mold opening and closing.

9.Adjustable movable plate mounting plate, makes the installation easier.

10.Mixed design of T-shape groove and die hole, increases universality of the mold.

Two.The Injection Section.

1.Bridge type support, improves injection smoothness.

2.Longer length-diameter ratio screw design, improves plasticizing effect.

3.Double seal structure, ensures no oil leakage.

4.Withhold type press plate, easy for debugging and assembly.

5.Bijection structure, improves stability.