Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

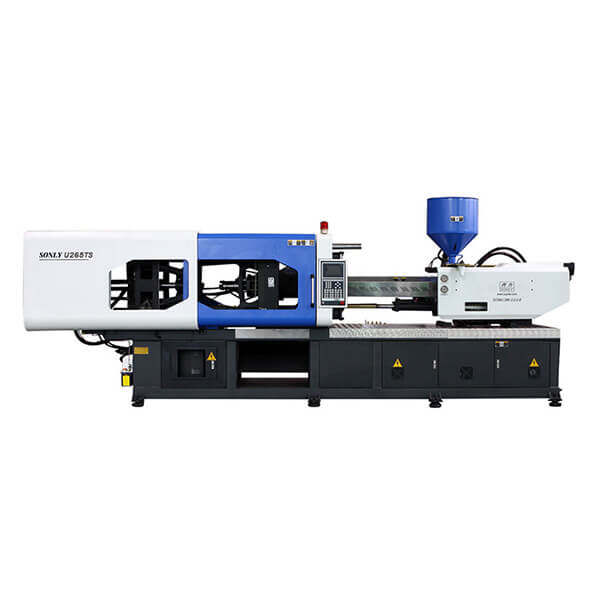

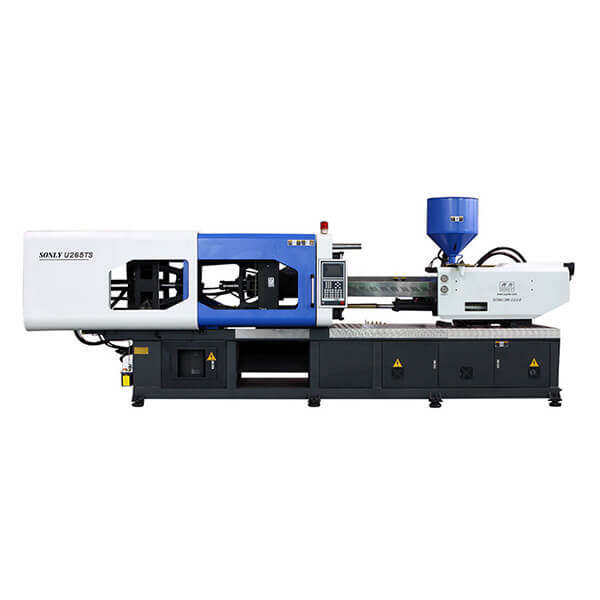

To better understand machine technology, it is important to use a common language for different drive technologies of modern injection molding machines.

According to the standards of the Plastics Industry Association (formerly SPI), an all electric machine has at least three spindles driven by servo motors (mold closing movement, injection and metering/plasticizing). The remaining 3 shafts (nozzle contact, ejection and mold height adjustment) can still be hydraulically driven.

The most efficient machine is capable of using a kinetic energy recovery system (KERS). This patented process uses a servo motor as a generator, which can collect all deceleration energy from each shaft and convert it into electrical energy. The converted energy is then fed back to the machine, usually for heating or control functions.

A machine with one or more of the three spindles hydraulically driven but at least one electrically driven is called a hybrid injection molding machine. One common example is the hydraulic injection molding machine with servo driven metering.

Metering is the largest energy absorption part of the machine (except for barrel heating). Therefore, it is a wise decision to use at least one servo electric drive device for metering. The hybrid injection molding machine is not a machine with a servo driven pump. Because all the movements behind the metering are still hydraulically driven.

Servo driven hydraulic machine is a full hydraulic injection molding machine. It uses a servo motor to drive the hydraulic pump. These machines often have a fixed displacement pump. But they may also have a variable displacement pump with a swashplate (usually DFEE or DFEC).