Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

silicone mould making machine For Sale is the equipment for making PVC products with production efficiency and quality. Just like the two ends of the rubber roller process, the most important thing is that we need to have a certain thickness of pressure when using it.

transfer moulding machine for sale Sales is used to manufacture plastic products, plastic moulding is a complex process that requires high precision. According to the shape of the product, it can be divided into two categories: one-piece injection molding and two-piece injection molding.

Injection molding machines are mainly used for plastic products of various tools, and perform various pneumatic, hydraulic or mechanical movements to achieve actions.

Wholesale hand moulding machine for sal is a first-class plastic production equipment, with multiple functions of any polyethylene foam molding plastic such as pipes, hoses, pipes, etc., easy to operate and low cost.

Injection molds are cheaper, lighter and more durable than metal molds, and are one of the key factors in reducing manufacturing costs. The precision of the molding process is directly related to how your product performs in terms of sales and growth.

The machine consisting of various sensors, technologies and adjustment devices is an advanced automation technology and a production equipment that realizes control. The low temperature and strength of a well-manufactured product, characterized by high strength or strength, using excellent processing equipment. Is the overall performance, continuous and high mechanical strength.

Injection molding machines are used to compress polystyrene or plastic raw materials so that they can be injected into metal molds. After cooling and hardening in the mold, the part is removed for use.

The purpose of the injection molding machine is to load the plastic resin into a special mold, then inject it into the mold cavity, and remove the molded product from the mold cavity. The volume and type of plastic resin varies with different orders and specifications. Therefore, the production process requires a variety of equipment models. It can be used to produce plastic products made of plastic materials, such as bottle caps, cup caps, tubes, etc.

In order to complete various tasks more efficiently, the other work of the machine is good. Other functions of the machine, the design of the machine can help you meet the processing needs with flexible arrangements of various processing tasks within a period of time.

Various machines of various high quality can be widely used to manufacture different products.

An inspection machine is a manufacturing tool, or used to make mold shapes with different properties, or various mold shapes with different properties.

Primarily a machine is an appliance that will be used to make solid or machined material into the finest industrial equipment materials. Only materials that produce the best performance, cleanest slurry appearance and water resistance.

Products are widely used in automotive electronics, medical and other industries. Furthermore, our products are used in many different fields.

The recycling machine is an efficient machine specially designed to recycle your PET bottles. It will grind your recycled plastic into small pieces, and then you can make useful things out of this recycled plastic.

Our injection molding machines are designed to be simple, robust and easy to operate to ensure high productivity. They are combined with the latest technology in a traditional way. Injection molding machines play a vital role in any plastic processing technology.

The meaning of the product shows: a machine is a machine that can convert a solid or liquid form in the form of solid or granules into a solid or liquid form. perform different operations.

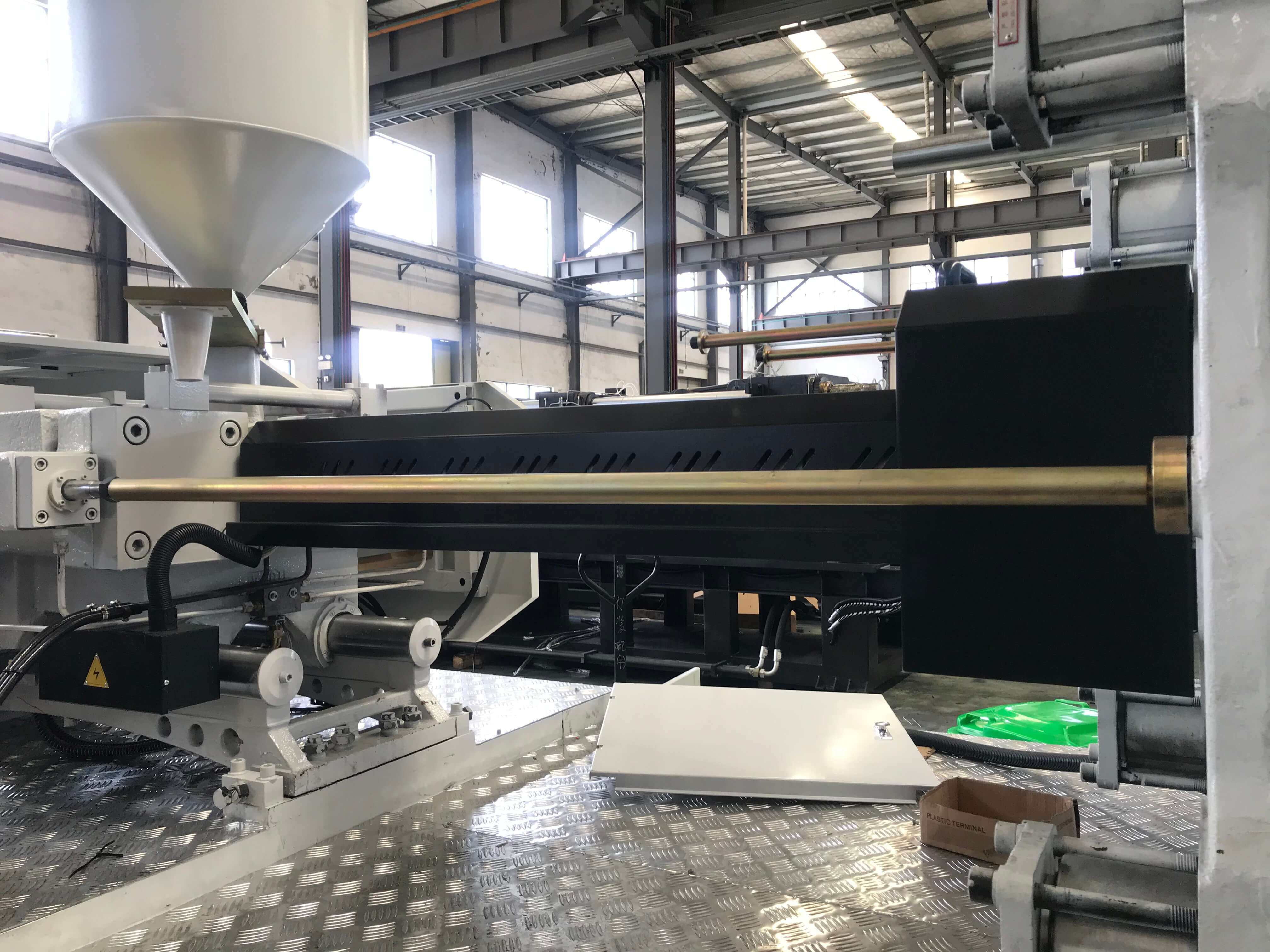

The purpose of an injection molding machine is to make plastic parts by injecting molten plastic into a mold. The main components of the injection molding machine are syringe, heating device, screw and barrel, mold clamping device, electric control cabinet, etc.

Plastic injection molding machines have many excellent features. It can be used for a variety of plastics, can produce a variety of products, and can meet the production requirements of some products.

Forming Machines Forming machines can be used to manufacture plastic articles. There are different types of plastics, but most are used to make toys and small household items because they are cheap and easy to manufacture.

The main components include barrel, nozzle, screw and upper die. The role of the injection molding machine is to melt plastic particles under pressure with thermal energy, inject them into the mold through a nozzle, and force them to achieve various production functions through appropriate heat treatment and mechanical deformation.