Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

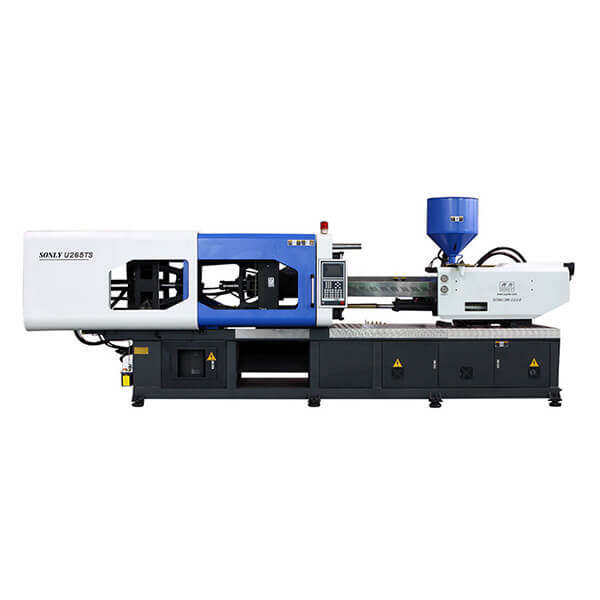

Becoming the first choice of energy saving for enterprises today, there are three main energy saving solutions for injection moulding machines. One is to retrofit the injection moulding machine with a frequency converter; the second is to adopt a new heating method for the heating barrel; the third is to use the heat from the heating part to bake the material. This can all serve the purpose of energy saving.

Most of the injection moulding machines are quantitative pump type injection moulding machines. The production cycle principle of the injection moulding machine is: close the mould ---- inject ---- hold pressure return ---- cooling ---- open the mould ---- eject.

With the addition of a frequency converter, the controller automatically detects the pressure and speed settings at all stages of the production process and calculates the corresponding proportional control signal output to the frequency converter. After receiving the control signal, the frequency converter dynamically adjusts the click speed to ensure that the hydraulic oil output from the oil pump produces as little reactive backflow as possible. This results in energy savings.

The heating method for injection moulding machines is generally electric heating, which transmits heat to the barrel through contact conduction. Only the heat immediately on the inside of the barrel surface is transferred to the barrel, most of the heat on the outside is dissipated into the air and there are heat transfer losses. The heat dissipation will cause the working temperature of the injection moulding machine to rise.

The induction heating technology causes the metal barrel to heat itself. And it can be wrapped with a certain amount of thermal insulation material on the outside of the barrel. This effectively reduces heat loss and increases thermal efficiency. The energy savings are therefore very significant, with system energy savings of 10% to 35%.

During the operation of the injection moulding machine, the heating ring heats up the barrel. And at the same time, some of the heat is still dissipated directly into the air. Traditional dryers, on the other hand, blow hot air into the barrel through a blower. Both cause a loss of energy and an increase in the temperature of the working environment.

The installation of waste heat recovery equipment for machines uses a closed-loop control concept for heat energy collection technology. It collect heat energy from the barrel of the injection moulding machine. The heat energy is then collected for reuse in baking material, and the wasted heat is collected and recycled. This will achieve the dual effect of both and improve the environment.